An ultra high pressure washer is an industrial water jetting system operating at pressures typically starting from 1,000 bar (15,000 PSI) and extending beyond 2,500–3,000 bar in specialised applications. At these pressure levels, water is no longer used only for surface cleaning—it becomes a precision removal tool capable of cutting, stripping, and disintegrating bonded materials such as coatings, corrosion, hardened deposits, and concrete.

Standard high pressure washers (usually below 500 bar) rely primarily on impact force and flow to remove loose contamination. Ultra high pressure systems, by contrast, use extreme jet velocity to generate shear forces that break the bond between the substrate and the contaminant. This allows ultra high pressure washers to perform tasks that conventional pressure washers cannot, including hydrodemolition, coating removal without abrasives, and internal pipe cleaning.

Ultra high pressure systems involve specialised pumps, reinforced hoses, precision nozzles, and strict safety controls. The energy density at these pressures presents serious risk if misused, requiring trained operators, regulated procedures, and industrial-grade infrastructure. For this reason, ultra high pressure washers are designed exclusively for professional applications in sectors such as construction, marine, petrochemical, power generation, and heavy manufacturing.

Ultra high pressure washers are selected based not only on maximum pressure, but on what type of material removal or surface treatment is required. Different pressure bands unlock very different industrial capabilities.

Systems operating in the 1,000–1,500 bar range are commonly used for heavy-duty industrial cleaning and surface preparation where conventional high pressure equipment is insufficient but controlled removal is still required.

일반적인 적용 분야는 다음과 같습니다.

This pressure range offers a strong balance between removal power and controllability, making it suitable for maintenance operations where substrate integrity must be preserved.

~에 1,500–2,000 bar, water jetting moves beyond cleaning into material separation and aggressive surface treatment. The jet velocity at this level allows effective bond breaking between coatings, corrosion layers, and base materials.

Common uses include:

This range is widely adopted in marine, petrochemical, and infrastructure maintenance due to its ability to remove stubborn materials without abrasive media.

Systems operating at 2,000–3,000 bar are used for specialised structural and demolition tasks. At these pressures, water becomes a precision tool capable of controlled material removal.

일반적인 적용 분야는 다음과 같습니다.

Because of the extreme energy involved, these systems require strict safety protocols, specialised accessories, and trained operators, and are typically deployed in large-scale construction and infrastructure projects.

While pressure determines cutting and penetration capability, flow rate controls productivity and removal speed. At ultra high pressure, insufficient flow can result in slow progress, inconsistent cleaning, or excessive dwell time on a single point.

Effective ultra high pressure systems balance:

In industrial applications, selecting pressure without considering flow rate often leads to underperforming systems or excessive operating time, increasing labour and operational costs.

Ultra high pressure water jetting is widely used in surface preparation where controlled material removal is required without introducing abrasive media or secondary contamination. Compared with blasting or mechanical methods, UHP systems offer higher precision, reduced waste, and better surface integrity.

Ultra high pressure washers remove paint, epoxy, and protective coatings by breaking the adhesive bond between the coating and the substrate. This allows complete stripping without embedding abrasive particles into the surface, making it particularly suitable for:

The process preserves the base material while producing a clean surface ready for inspection or recoating.

For corroded steel, ultra high pressure jets penetrate beneath corrosion layers and lift rust from the surface without grinding or heat input. This method is commonly applied in:

UHP cleaning removes corrosion while minimising material loss, helping extend asset service life.

Ultra high pressure water jetting can be used to create a controlled surface profile that improves coating adhesion. Unlike abrasive blasting, the resulting profile is uniform and free from embedded media, reducing the risk of coating failure and contamination.

This makes UHP systems suitable for:

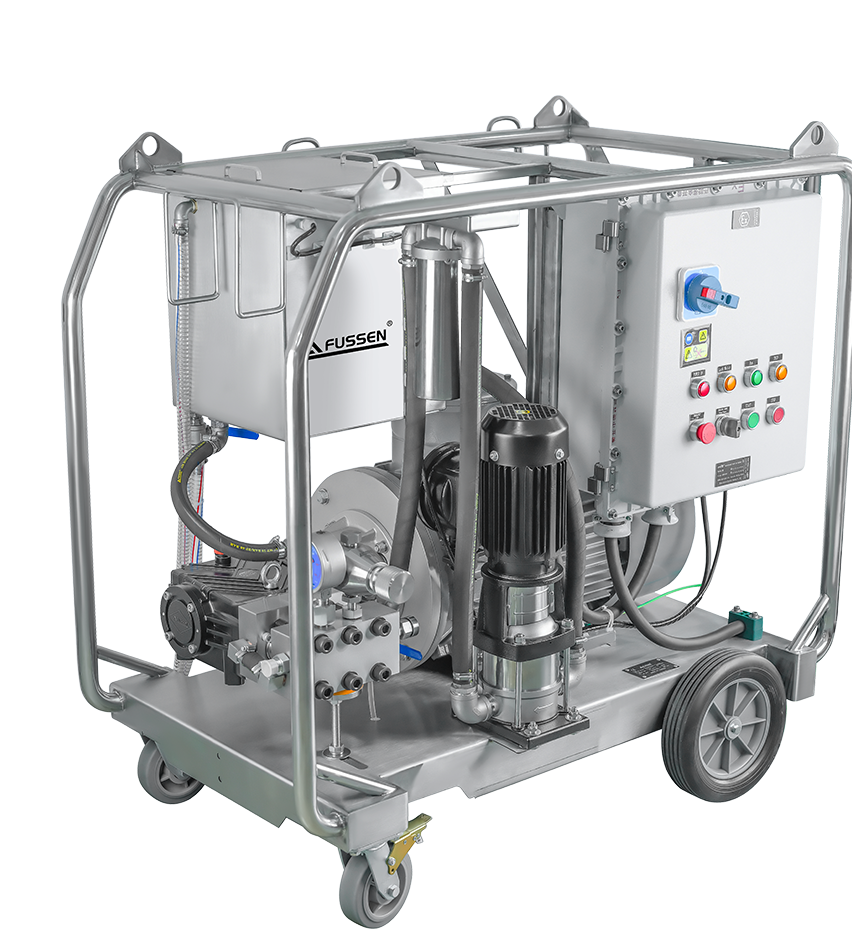

For surface preparation applications, Fussen offers ultra high pressure solutions engineered for stable output, durability, and industrial-duty operation, including:

These systems can be configured with appropriate nozzles, pressure regulation, and safety features to match specific surface preparation requirements.

Hydrodemolition uses ultra high pressure water jets to remove deteriorated concrete in a controlled and selective manner, preserving structural integrity while preparing surfaces for repair or reinforcement. It is widely adopted in civil engineering projects where precision and substrate protection are critical.

Ultra high pressure water jetting removes weakened or damaged concrete while leaving embedded steel reinforcement intact. Unlike mechanical demolition, the process does not generate vibration or micro-cracking, reducing the risk of secondary structural damage. This makes hydrodemolition particularly suitable for repair projects requiring strict quality control.

Hydrodemolition is commonly used in:

The method allows targeted removal of compromised concrete while maintaining bond strength between existing and new repair materials.

Compared with jackhammers and milling equipment, hydrodemolition offers several operational advantages:

These benefits contribute to longer repair life and reduced rework in critical infrastructure projects.

For hydrodemolition and heavy concrete removal applications, Fussen provides ultra high pressure systems engineered for extreme pressure stability, continuous operation, and on-site mobility, including:

These systems can be configured with appropriate lances, nozzles, pressure controls, and safety features to meet project-specific hydrodemolition requirements.

Ultra high pressure water jetting is widely used in shipbuilding and marine maintenance due to its effectiveness in removing coatings, corrosion, and marine growth without introducing abrasive media. The method supports faster turnaround, reduced waste handling, and improved surface integrity in harsh saltwater environments.

Ultra high pressure washers are used to remove antifouling coatings, marine paints, and biological growth from vessel hulls. The high-energy water jet breaks the bond between the coating and steel surface without embedding abrasive particles, making it suitable for:

This approach reduces secondary contamination and simplifies waste collection compared to blasting methods.

Inside ballast tanks and cargo holds, ultra high pressure systems provide effective cleaning in confined and corrosion-prone spaces. UHP jetting removes scale, rust, and coating residues while avoiding sparks and heat, which is critical for safety and compliance in enclosed marine environments.

Ultra high pressure washers are also deployed for maintenance of offshore platforms, piers, and marine steel structures exposed to constant saltwater and weathering. The method allows precise corrosion removal and surface preparation without damaging structural components, supporting long-term asset protection.

을 위한 marine and offshore applications, Fussen offers ultra high pressure solutions designed to withstand corrosive environments and continuous-duty operation, including:

These systems can be configured with marine-grade fittings, appropriate nozzles, and safety controls to meet shipbuilding and offshore maintenance requirements.

Ultra high pressure water jetting is widely applied in petrochemical plants and refineries where heavy fouling, hardened residues, and strict safety regulations make conventional cleaning methods impractical or risky. UHP systems provide non-sparking, controlled material removal with minimal secondary contamination.

Ultra high pressure washers are used to remove scale, deposits, and process residues from heat exchangers, reactors, and pressure vessels. High-energy water jets penetrate narrow passages and internal surfaces, restoring heat transfer efficiency without mechanical abrasion or chemical exposure.

This approach supports faster turnaround during shutdowns and reduces the risk of damage to critical process equipment.

In refinery and petrochemical operations, UHP jetting is effective for removing:

These materials often resist chemical cleaning and mechanical scraping. Ultra high pressure water jetting breaks their adhesion to metal surfaces while avoiding thermal stress or ignition risks.

Ultra high pressure cleaning is suitable for ATEX-regulated and hazardous areas cleaning because it avoids sparks, open flames, and abrasive dust. Systems can be configured for remote operation, allowing cleaning to be performed at a safe distance while maintaining precise control over pressure and flow.

For petrochemical and refinery applications, Fussen provides ultra high pressure solutions engineered for continuous operation, high reliability, and compliance-focused environments, including:

These systems can be integrated with plant safety protocols, automated controls, and specialised nozzles to meet refinery-specific operational requirements.

Ultra high pressure water jetting is widely used for internal cleaning of pipelines, tubes, and heat exchangers where fouling, scale, and blockages restrict flow and reduce operational efficiency. UHP systems provide effective internal cleaning without dismantling equipment or introducing chemical agents.

Ultra high pressure jets remove mineral scale, hardened deposits, and process residues from the internal walls of pipes and tubes. The high-energy water stream breaks deposits away from the pipe surface and flushes them out of the system, restoring flow capacity and improving system performance.

This method is commonly applied in:

For internal cleaning applications, ultra high pressure systems are typically paired with rotary or multi-jet nozzles. These nozzles rotate under water pressure, directing jets evenly around the internal circumference of the pipe or tube. This ensures uniform cleaning while reducing the risk of localized erosion or uneven material removal.

Different nozzle designs can be selected based on pipe diameter, deposit type, and required cleaning intensity.

Compared with chemical cleaning, ultra high pressure water jetting offers several operational advantages:

These factors make UHP cleaning particularly suitable for facilities aiming to minimise downtime, environmental impact, and regulatory complexity.

For pipeline, tube, and heat exchanger cleaning, Fussen offers ultra high pressure solutions engineered for precision control and internal cleaning efficiency, including:

These systems can be configured to meet specific pipe diameters, materials, and operational constraints while maintaining safe and consistent cleaning performance.

Ultra high pressure water jetting is widely used for cleaning heavy machinery and industrial equipment where contamination is thick, hardened, and difficult to remove using conventional methods. UHP systems enable effective cleaning while reducing downtime and avoiding equipment disassembly.

In mining and construction operations, ultra high pressure washers are used to remove compacted mud, grease, scale, and material build-up from equipment such as excavators, loaders, crushers, and conveyors. The high-energy water jet penetrates dense contamination without damaging structural components, supporting faster maintenance cycles and improved equipment availability.

Ultra high pressure systems are commonly applied in cement plants, steel mills, and power generation facilities to clean:

UHP jetting removes hardened deposits that would otherwise require mechanical chipping or chemical treatment, improving safety and reducing labour intensity.

One of the key advantages of ultra high pressure cleaning is the ability to remove stubborn deposits in situ, eliminating the need for dismantling large or complex equipment. This reduces downtime, minimises exposure to confined spaces, and lowers overall maintenance costs while maintaining effective cleaning results.

For heavy machinery and industrial equipment cleaning, Fussen offers ultra high pressure solutions designed for mobility, durability, and on-site efficiency, including:

These systems can be configured to match specific equipment types, contamination levels, and site conditions.

Ultra high pressure water jetting is increasingly used in public infrastructure maintenance where durability, precision, and minimal disruption are required. UHP systems support effective removal of worn materials while preserving underlying structures and reducing environmental impact.

Ultra high pressure washers are applied in bridge decks, tunnel linings, and concrete support structures to remove deteriorated material, corrosion, and surface contamination. The controlled removal process avoids vibration and micro-cracking, making it suitable for ageing infrastructure where structural integrity must be maintained during maintenance and repair work.

UHP systems are used to remove road markings, thermoplastic layers, and surface coatings without damaging asphalt or concrete substrates. This method enables precise removal with minimal surface wear, supporting road resurfacing, re-marking, and traffic management projects where speed and surface quality are critical.

In urban environments, ultra high pressure water jetting is used for refurbishing public assets such as:

The process offers reduced dust, lower noise compared to mechanical methods, and improved safety in densely populated areas.

For infrastructure and public works applications, Fussen offers ultra high pressure solutions designed for municipal reliability, mobility, and continuous operation, including:

These systems can be configured to meet municipal standards, project-specific specifications, and operational safety requirements.

Ultra high pressure water jetting and abrasive blasting are both established surface treatment methods, but they differ significantly in how material is removed, how waste is managed, and how long-term costs are incurred. The choice between them depends on surface condition, environmental constraints, and project objectives.

Ultra high pressure water jetting removes coatings, corrosion, or concrete by breaking the bond between the unwanted material and the substrate. Because the process introduces no abrasive media, it preserves the base material and avoids embedding foreign particles into the surface. This is particularly important for steel structures, reinforced concrete, and critical components where surface integrity affects long-term performance.

Abrasive blasting, by contrast, relies on mechanical impact. While effective, it can:

For applications where material preservation and controlled removal are required, ultra high pressure jetting offers a clear technical advantage.

Ultra high pressure water jetting generates waste primarily in the form of water and removed material, which can often be filtered, contained, and treated on site. There is no abrasive media to recover, recycle, or dispose of, significantly reducing waste volume and handling complexity.

Abrasive blasting produces large quantities of spent media mixed with removed coatings and contaminants. This waste typically requires:

In environmentally sensitive areas or regulated industrial sites, water jetting simplifies compliance and reduces environmental impact.

While ultra high pressure systems may have higher initial equipment costs, they often deliver lower total cost of ownership over time. Factors contributing to this include:

Abrasive blasting may appear cost-effective for short-term or small-scale projects, but ongoing media consumption, waste handling, and surface remediation can increase long-term expenses.

In industrial and infrastructure applications where efficiency, environmental control, and surface quality are critical, ultra high pressure water jetting is increasingly selected as the preferred method.

Ultra high pressure water jetting and chemical cleaning are both used to remove heavy fouling and deposits in industrial environments. However, they differ significantly in safety profile, environmental impact, and operational control, which directly affects method selection in regulated industries.

Ultra high pressure water jetting relies on mechanical energy rather than chemical reaction. While strict safety procedures and trained operators are required due to the high energy involved, the process eliminates risks associated with:

In many jurisdictions, UHP cleaning simplifies compliance with occupational health and safety regulations because it avoids chemical storage, transport, and exposure controls. Chemical cleaning, by contrast, often requires extensive permitting, containment measures, and specialised handling procedures.

Ultra high pressure cleaning produces wastewater containing removed material, which can typically be filtered, neutralised, and treated using standard industrial wastewater processes. There are no spent chemicals to neutralise or dispose of, reducing environmental burden and disposal complexity.

Chemical cleaning generates liquid waste streams that may contain acids, solvents, or inhibitors. These wastes often require:

For facilities aiming to reduce environmental impact and wastewater treatment complexity, ultra high pressure jetting is often the preferred option.

Chemical cleaning remains appropriate in certain situations where:

In practice, many facilities adopt a hybrid approach, using ultra high pressure water jetting for bulk material removal and chemical cleaning for final residue treatment where necessary.

The choice between electric and diesel ultra high pressure systems depends on installation environment, power availability, mobility requirements, and duty cycle expectations. Both options are widely used in industrial applications, but each serves different operational needs.

Electric ultra high pressure systems are commonly selected for fixed installations in refineries, power plants, manufacturing facilities, and shipyards with reliable electrical infrastructure. These systems offer stable output, lower noise levels, and zero on-site emissions, making them suitable for indoor or environmentally controlled environments.

Electric-driven UHP units are often integrated into permanent cleaning stations or centralised maintenance systems, where consistent power supply and continuous operation are required.

Diesel ultra high pressure systems are preferred for mobile, outdoor, or remote applications where electrical power is unavailable or impractical. Typical use cases include infrastructure projects, marine maintenance, mining sites, and emergency repair operations.

Diesel systems provide self-contained power, enabling rapid deployment and flexible operation across multiple locations. Trailer-mounted and truck-mounted configurations are commonly used to support large-scale or geographically dispersed projects.

Both electric and diesel systems can be engineered for continuous-duty operation, but power source selection affects system design and operating characteristics. Electric systems benefit from consistent power delivery and simplified maintenance, while diesel systems offer operational independence at the cost of fuel management and emissions considerations.

언제 specifying an ultra high pressure system, evaluating power availability, operating duration, environmental constraints, and total cost of ownership is essential to selecting the most appropriate drive configuration.

Ultra high pressure typically refers to water jetting systems operating at 1,000 bar (15,000 PSI) or higher. Many industrial applications use systems in the 1,500–3,000 bar range, depending on the task, material type, and required removal depth.

In many applications, ultra high pressure water jetting can replace sandblasting, particularly for coating removal, corrosion cleaning, and surface preparation. UHP cleaning avoids abrasive media, reduces waste, and preserves the base material. However, abrasive blasting may still be used where specific surface roughness profiles or very high production speed are required.

When properly specified and operated, ultra high pressure water jetting is safe for both steel and concrete. Pressure, nozzle type, standoff distance, and flow rate must be matched to the material and condition of the surface. Incorrect settings or untrained operation can cause damage, which is why UHP systems are used only by trained professionals.

Industrial ultra high pressure systems are designed for continuous-duty operation, often running for extended periods during maintenance shutdowns or infrastructure projects. Actual runtime depends on pump design, cooling, lubrication, and maintenance schedules. Properly engineered systems can operate reliably throughout full work shifts.

Ultra high pressure pumps require routine inspection of seals, valves, and lubrication systems. Maintenance intervals depend on operating pressure, water quality, and duty cycle. Using clean, filtered water and following manufacturer service guidelines is essential to maintaining pump life and performance.

퓌센 develops ultra high pressure washer systems specifically for heavy industrial, infrastructure, and process-critical applications where stability, control, and long-term reliability are non-negotiable. System design is centred on robust plunger pump engineering, precise pressure regulation, and configurations capable of sustained operation under extreme loads.

Rather than offering generic machines, Fussen provides application-matched UHP solutions, ranging from mobile diesel-driven units for field operations to stationary ultra high pressure pump stations integrated into industrial plants. Each system is configured according to pressure range, flow requirements, duty cycle, and operating environment to ensure consistent performance and safe operation.

By combining pump durability, pressure stability, and flexible system design, Fussen supports industries where ultra high pressure water jetting is used not as a cleaning tool alone, but as a controlled material removal and maintenance technology. Speak with us now and see how we can help your next project.