High Pressure Washer Applications in Marine Industry

High-pressure washers have become essential tools in the marine industry, where salt, marine growth, and oil residues constantly threaten vessel performance and safety. From hull cleaning and biofouling control to maintaining clean decks, cargo holds, and ballast tanks, these systems address demanding operational and regulatory requirements. Their role extends from routine maintenance to specialized offshore tasks, raising important questions about appropriate equipment selection and the technical features that truly withstand harsh marine conditions.

High-pressure washers have become essential tools in the marine industry, where salt, marine growth, and oil residues constantly threaten vessel performance and safety. From hull cleaning and biofouling control to maintaining clean decks, cargo holds, and ballast tanks, these systems address demanding operational and regulatory requirements. Their role extends from routine maintenance to specialized offshore tasks, raising important questions about appropriate equipment selection and the technical features that truly withstand harsh marine conditions.

With more than 25 years of experience in high-pressure washer and high pressure pump, Fussen has supported shipyards, offshore operators, and vessel maintenance teams globally. As an active member of IMPA (International Marine Purchasing Association), the company works closely with marine procurement professionals to ensure that high-pressure cleaning systems meet the reliability, safety, and performance standards required in today’s harsh marine environments.

Key Takeaways

- Hull and underwater cleaning removes biofouling, barnacles, and algae to restore hydrodynamic performance and reduce fuel consumption.

- Deck, superstructure, and walkway washing clears salt, dirt, and spills, improving safety, appearance, and anti-slip performance.

- Cargo hold, ballast tank, and internal compartment cleaning removes residues and deposits, preventing contamination, corrosion, and microbial growth.

- Engine room and machinery cleaning strips oil, grease, and carbon deposits, lowering fire risk and improving equipment reliability.

- Rust, scale, and old paint removal via high- or ultra-high-pressure jetting prepares steel surfaces for recoating and extends coating system life.

Introduction: Why High-Pressure Washers Matter in the Marine Industry

In modern vessel maintenance, high-pressure washer has become a core method for removing fouling, coatings, and contaminants without excessive manual labor or abrasive blasting. By matching pressure, flow, and power source to each task, ship operators can maintain hulls, decks, tanks, and machinery more consistently and with less downtime. For shipyards and marine service companies, this translates into faster turnaround times, reduced consumable use, and more predictable maintenance schedules.

The role of water jet cleaning in modern vessel maintenance

High-pressure water jet cleaning has become a core technology in modern vessel maintenance, enabling shipowners and yards to combat fouling, corrosion, and contamination more efficiently than traditional methods. As hull coatings, steel surfaces, and internal tanks face constant exposure to saltwater, cargo residues, and marine growth, the high pressure washer has evolved into a standard tool for marine industry cleaning.

Using controlled pressures from roughly 150 to 1000 bar, operators can remove algae, barnacles, rust scales, and aged coatings while limiting substrate damage and reducing chemical dependence. Water jet cleaning suits hulls, decks, cargo holds, ballast tanks, and engine rooms, where access is difficult and cleanliness standards are strict. This approach underpins safer, more consistent surface preparation across modern fleets.

Efficiency gains for shipyards and marine service companies

Across shipyards and marine service companies, modern high-pressure washers have become a primary lever for improving cleaning productivity, turnaround speed, and labor efficiency. When hull preparation, deck washing, and tank cleaning can be completed faster, dock time shortens and vessel availability rises. A well-specified marine pressure washer replaces multiple traditional tools, reduces manual scraping, and cuts rework caused by inconsistent surface preparation.

- Shorter project cycles-Faster rust and coating removal helps shipyards meet tight dry-dock schedules and avoid costly overruns.

- Lower labor intensity -Concentrated water jet energy lets smaller teams handle large-surface tasks with less physical strain.

- Higher equipment utilization-Durable ship cleaning equipment with stable pressure output minimizes breakdowns, keeping blasting, painting, and repair workflows continuous.

Common Marine Cleaning Challenges and Surface Contaminants

Marine maintenance teams must constantly address stubborn marine growth, crystallized salt deposits, baked-on oil residues, and progressive corrosion across hulls, decks, and machinery. These contaminants not only reduce efficiency and safety, but also demand more aggressive and consistent cleaning performance than typical industrial settings. Because equipment operates in humid, salt-laden, and often remote or hazardous locations, marine environments impose strict requirements on washer durability, corrosion resistance, and uptime.

Marine growth, salt deposits, oil residues, and corrosion

Although every vessel and offshore structure operates in different conditions, they all face the same core contaminants: stubborn marine growth, crystallized salt deposits, tenacious oil and grease films, and progressive corrosion. Biofouling layers increase drag on hulls, while salt crystals creep into seams and fittings, accelerating rust and undermining coatings. Oil residues accumulate on decks, engine rooms, and cargo areas, creating slip hazards and complicating inspections.

- Marine growth bonds tightly to coatings, demanding consistent high-pressure impact for efficient removal.

- Salt deposits and corrosion often require targeted marine rust removal before recoating or structural repairs.

- Oil and grease films on work areas are best controlled with a deck cleaning pressure washer, restoring grip, cleanliness, and readiness for subsequent maintenance tasks.

Why marine environments demand higher durability and uptime

Because vessels, rigs, and dockside facilities operate in a constant cycle of exposure, cleaning, and inspection, marine environments place unusually high demands on the durability and uptime of high-pressure washers. Equipment must withstand salt-laden atmospheres, constant vibration, temperature swings, and abrasive contaminants such as sand, rust scale, and marine growth.

Any unplanned stoppage quickly disrupts schedules, delays inspections, and extends dry-dock or port stays. As a result, marine-grade cleaning equipment is built around robust components, especially the high-pressure plunger pump, which must deliver consistent pressure for long-duty shifts without overheating or premature seal wear. Corrosion-resistant materials, reinforced frames, and protective coatings are essential, ensuring systems remain operational across repeated cleaning campaigns in highly aggressive coastal and offshore conditions.

High-Pressure Washing for Ship Hull Cleaning & Biofouling Removal

High-pressure washing plays a central role in restoring ship hull performance by mechanically removing barnacles, algae, and other biological fouling that increase drag and fuel consumption. By applying controlled pressure and flow, operators can strip away marine growth while preserving the integrity of underlying steel and coatings. This process also prepares hull steel surfaces for repainting or recoating, creating a clean, adherent substrate for modern marine protective systems.

Removing barnacles, algae, and biological fouling

Marine operators confront biofouling on every voyage, as barnacles, mussels, algae, and slime rapidly colonize hulls, sea chests, and underwater appendages. Hull cleaning high pressure systems allow teams to dislodge stubborn growth while preserving sound coatings, reducing drag and fuel consumption. By adjusting pressure and flow, operators can work from light slime removal to more aggressive marine paint removal where coatings are already compromised.

- Barnacle and mussel removal - Concentrated jets break the mechanical bond at the shell–coating interface, minimizing chisel work and diver time.

- Algae, slime, and weed stripping - Wider nozzles sweep large areas quickly, restoring hydrodynamic smoothness.

- Sea chest and grid cleaning - Compact lances clear grates and intakes, preventing cooling losses and pump cavitation.

Preparing steel surfaces for repainting or coating

Preparing steel surfaces for repainting or coating demands more than simply blasting away loose material; it requires controlled, consistent energy that exposes clean, sound metal without damaging the substrate. In marine environments, high-pressure washers are used to strip weakened coatings, soluble salts, and micro-fouling from hull plates, tank interiors, and structural steel prior to abrasive blasting or direct recoating. Correct pressure and flow settings help achieve the required surface cleanliness grade while minimising flash rust and substrate loss.

The same approach supports cargo hold cleaning, where residues and spot corrosion must be removed to meet coating manufacturers specifications. As core shipyard maintenance tools, high-pressure units shorten dry-dock schedules, improve coating adhesion, and create a more predictable substrate for long-life protective systems.

Deck, Superstructure, and Onboard Surface Cleaning Applications

Deck, superstructure, and onboard surface cleaning place continuous demands on high-pressure washer performance, as these areas are exposed daily to salt spray, foot traffic, and operational spills. Daily deck washing is essential to manage saltwater corrosion, remove slippery contaminants, and maintain safe working conditions. At the same time, targeted cleaning of handrails, equipment housings, and walkways requires controlled pressure and suitable nozzles to protect coatings and sensitive fittings while keeping access routes clean.

Daily deck washing and saltwater corrosion management

Daily deck washing is the frontline defense against saltwater corrosion and slippery, unsafe working surfaces on board. Continuous spray and dried salt crystals attack coatings, deck fittings, and weld seams in much the same way they threaten internal structures during ballast tank flushing or exposed structures during offshore platform cleaning. High-pressure washers allow crews to strip salt films, oil drips, and loose rust before they become repair jobs.

Key practices typically include:

- Using medium pressure (around 150-250 bar) for routine washdowns to remove salt without damaging coatings.

- Targeting scuppers, deck drains, and weld toes where standing water accelerates pitting and under-film corrosion.

- Establishing daily and post-voyage cleaning routines, supported by reliable electric or diesel units engineered for long-duty marine operation.

Cleaning handrails, equipment housings, and walkways

Beyond open deck areas, much of the day‑to‑day safety and appearance of a vessel depends on how effectively handrails, equipment housings, and walkways are kept clean. These surfaces accumulate salt, oil mist, soot, and airborne rust, which can quickly reduce grip, obscure markings, and degrade coatings.

High‑pressure systems allow crews to flush contaminants from complex geometries around valves, junction boxes, winches, and guardrails without disassembly. An electric shipyard pressure washer offers consistent power and low noise for routine cleaning alongside other maintenance tasks. On tankers, gas carriers, or drilling units, an explosion-proof pressure washer is essential where flammable vapors may be present, allowing operators to maintain anti-slip walkways, ladders, and access platforms while complying with ATEX/Ex safety requirements.

Cargo Hold, Ballast Tank, and Internal Compartment Washing

Cargo holds, ballast tanks, and internal compartments place particular demands on high-pressure cleaning systems due to persistent cargo residues and chemical deposits on steel surfaces. In these confined areas, operators must control pressure, flow, and nozzle patterns to dislodge stubborn layers without damaging coatings or structures. At the same time, limited ventilation and drainage inside tanks require equipment and procedures that manage overspray, wastewater, and vapors to maintain safe working conditions.

Flushing cargo residues and chemical deposits

Flushing cargo residues and chemical deposits from cargo holds, ballast tanks, and internal compartments demands controlled high-pressure water jetting that can penetrate stubborn layers without damaging coatings or structure. Operators rely on adjustable pressure, high flow flushing, and suitable nozzles to dislodge dry bulk remnants, scale, and crystallized chemicals, while maintaining acceptable surface roughness for recoating and safe ballasting.

1. Safety in hazardous zones

When residues release flammable vapors, an ATEX pressure washer enables compliant cleaning without introducing ignition sources in classified spaces.

2. Product-change turnaround

Thorough flushing minimizes cross-contamination when switching between incompatible cargoes, supporting faster, audit-ready changeovers.

3. Corrosion and sludge control

Regular internal washing limits acidic deposits, microbial-induced corrosion, and sludge buildup that can compromise tank integrity and pumping efficiency.

Addressing ventilation and drainage limitations inside tanks

Effective tank cleaning is often constrained less by pressure capacity than by limited ventilation and drainage, especially in deep cargo holds, ballast tanks, and narrow internal compartments. Poor air exchange and slow water evacuation increase humidity, hinder visibility, and raise confined-space risk. High-pressure solutions must thus pair hydraulic performance with careful control of water volume and spray pattern.

Using a ceramic plunger marine pump, operators can maintain stable pressure at moderated flow, reducing pooling while still breaking rust, scale, and residue. Diesel marine pressure washer units are positioned outside the compartment, supplying high-pressure water through extended hoses to minimize exhaust and heat inside tanks. Combined with temporary sump pumps and forced ventilation, this approach supports safer, more efficient internal tank washing.

Rust, Scale, and Old Paint Removal in Shipyard Maintenance

In shipyard maintenance, rust, scale, and aged coatings are often removed using either high-pressure or ultra-high-pressure water jetting, each suited to different levels of buildup and productivity targets. The chosen pressure regime directly affects surface cleanliness, from simple coating removal to achieving near-white metal standards. By optimizing these settings, contractors can greatly improve coating adhesion and extend the service life of new protective paint systems.

High-pressure vs ultra-high-pressure paint stripping

While many marine cleaning tasks can be handled with conventional pressure levels, rust, scale, and aged coatings in shipyard maintenance often demand a clear distinction between high-pressure and ultra-high-pressure paint stripping. In practice, high-pressure water jetting (typically 150-1000 bar) suits general coating removal and surface cleaning, while ultra-high-pressure (UHP) systems exceed this range to cut through thick, tightly bonded marine coatings. Fussen designs both categories to address varying shipyard demands efficiently and safely.

1.High-pressure systems - Practical for routine hull, deck, and superstructure stripping with moderate coating thickness.

2.UHP systems - Selected for heavy rust, multi-layered epoxies, and localized scale removal.

3.Selection factors - Coating type, substrate sensitivity, access constraints, and available power determine whether high-pressure or UHP is deployed.

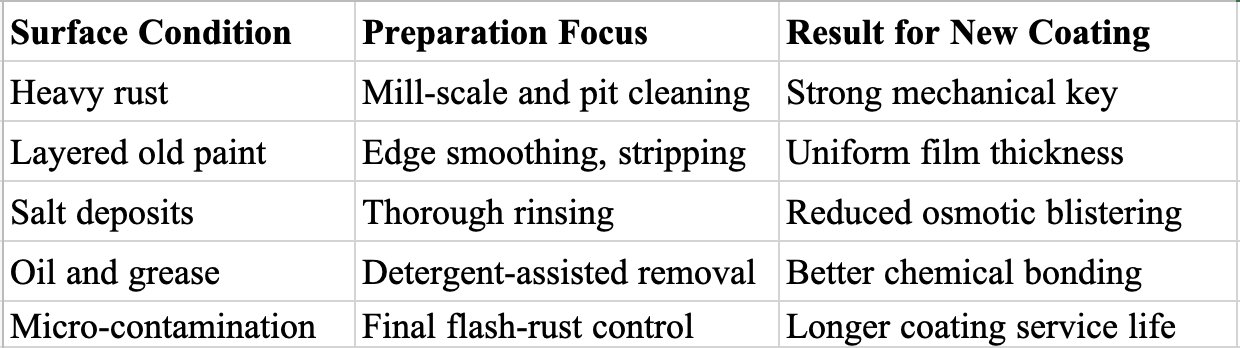

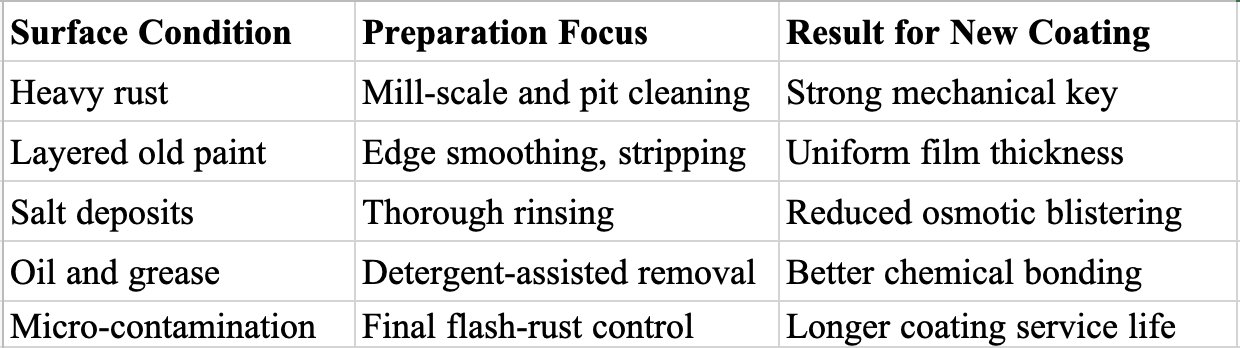

Improving coating adhesion through proper surface preparation

Surface preparation stands at the core of durable marine coatings, and high-pressure water jetting has become a primary tool for achieving it. In shipyards, adhesion failures usually trace back to residual rust, scale, soluble salts, or feathered old paint. By delivering controlled pressures from 150-1000 bar with sufficient flow, systems such as Fussen’s marine-focused units expose clean, angular profiles without embedding contaminants.

Proper jetting, followed by timely coating, secures adhesion in harsh marine exposure.

Marine Engine Room and Machinery Cleaning Requirements

In marine engine rooms, effective high-pressure cleaning is essential for removing heavy oil, grease, and carbon deposits from engines, pumps, generators, and auxiliary systems. These tasks must be carried out without damaging sensitive components, insulation, or coatings that protect against corrosion and heat. At the same time, operators must select pressure washers and accessories that are safe for confined, poorly ventilated machinery spaces, with careful consideration of power source, explosion protection, and ergonomic access.

Degreasing engines, pumps, generators, and auxiliaries

Engines, pumps, generators, and auxiliary systems in marine engine rooms accumulate stubborn layers of oil, fuel residues, carbon deposits, and emulsified grime that compromise safety and reliability. High-pressure water jetting allows targeted degreasing of these components without excessive chemical use or manual scraping, reducing fire loads and improving heat transfer on casings and coolers. Using appropriately selected pressures and fan nozzles, operators can remove surface contamination while preserving paint, insulation, and gasket integrity.

1.Engines and turbochargers - flushing external block surfaces, sumps, and housings to expose leaks and ease inspections.

2.Pumps and compressors - clearing oil film from casings, bases, and couplings to prevent slippage.

3.Generators and auxiliaries - cleaning skid frames, drip trays, and pipework to maintain orderly, low-risk machinery spaces.

Selecting safe equipment for confined machinery spaces

Few environments demand more careful equipment selection than confined marine machinery spaces, where heat, noise, tight clearances, and flammable atmospheres converge. Here, pressure washers must combine compact dimensions, stable pressure output, and strict safety compliance. Electric units are generally preferred over diesel to minimise exhaust, heat, and ignition risks, especially when ventilation is limited.

Where vapours or mist may form explosive atmospheres, ATEX/Ex-proof certified systems and control panels become essential. Fussen’s explosion-proof electric models, with soft-start controls and sealed components, help reduce arcing hazards around fuel lines, hot surfaces, and cable runs. Corrosion-resistant pump bodies, marine-grade seals, and stainless frames prevent fluid leaks that could compromise footing. Clear hose routing, emergency-stop integration, and low-noise designs further support safe engine room cleaning.

Offshore Platform and Terminal Maintenance Applications

Offshore platforms and marine terminals face rapid rust formation, scale buildup, and persistent oil contamination across wide structural surfaces. High-pressure water jetting becomes a primary tool for stripping corrosion products from steel legs, decks, and riser areas while preserving structural integrity. In parallel, high-flow systems enable fast flushing of large decks, loading zones, and spill areas, helping operators restore safe, non-slippery working conditions.

Removing rust and scale from offshore structures

Constant exposure to saltwater, waves, and fluctuating temperatures causes rapid rusting and scale buildup on offshore platforms, jetties, and loading terminals, compromising both structural integrity and safety. High-pressure water jetting allows maintenance teams to remove corrosion products without excessive heat, dust, or secondary contamination. By selecting pressures in the 300-1000 bar range and matching nozzles to surface condition, operators can reach crevices, brace connections, and tidal zones that are difficult to access with mechanical tools.

1.Restore steel thickness visibility before NDT inspections and coating surveys.

2.Prepare clean, profiled surfaces for primer and anti-corrosion coating systems.

3.Reduce manual chipping and grinding, lowering worker fatigue and improving safety.

Fussen’s corrosion-resistant triplex plunger pumps provide stable pressure for long offshore shifts.

High-flow flushing for large areas and oil-contaminated surfaces

Beyond local rust removal, offshore platforms and terminals also demand rapid cleaning of broad decks, walkways, and loading zones that are frequently contaminated with oil, grease, and process residues. In these environments, high-flow flushing becomes more important than ultra-high pressure. Operators rely on large-volume units to push, dilute, and lift contaminants away from working areas, drain channels, and containment barriers without damaging coatings or anti-slip surfaces.

Fussen’s high-flow electric and diesel systems, often operating between 150-250 bar and up to 120 L/min, are suited to such tasks. Large-area lances, surface bars, and boom-mounted tools allow efficient coverage of helidecks, loading manifolds, and pipe alleys. Explosion-proof configurations support safe cleaning in classified zones near crude, fuel, and chemical transfer equipment.

Choosing the Right Pressure Level (150–1000 bar) for Marine Tasks

Selecting the correct pressure level between 150 and 1000 bar is critical to balancing cleaning efficiency with surface protection on hulls, decks, and sensitive onboard equipment. Lighter tasks such as routine deck rinsing or non-coated equipment cleaning often perform best at the lower end of this range, while heavy hull fouling, rust layers, or coating removal demand higher intensities. This section outlines how maintenance teams can match bar levels to specific marine jobs and decide when to step up from high pressure to very high pressure for demanding applications.

Matching PSI/bar to hull, deck, and equipment cleaning

A precise match between pressure level and task is essential when using high-pressure washers on hulls, decks, and onboard equipment in marine environments. Operators must balance effective fouling removal with protection of coatings, sealants, and sensitive components. Fussen’s systems, spanning 150-1000 bar, allow fine-tuning for each surface and contamination type.

1. Hull cleaning (anti-fouling and fouling removal)

- 150-300 bar suits routine rinsing of painted hulls;

- 300-500 bar targets heavier slime, barnacle bases, and light rust without stripping sound coatings.

2. Deck and superstructure washing

- 150-250 bar is typically used on painted decks, handrails, and walkways to remove salt, oil, and light corrosion.

3. Equipment and machinery surfaces

- 200-400 bar addresses grease, oil, and rust on winches, cranes, and engine-room components, adjusted to material strength.

When to choose high pressure vs very high pressure

When should marine operators step up from standard high pressure to very high pressure water jetting? In practice, 150-250 bar typically covers routine deck cleaning, light salt deposits, and wash-down of machinery where coatings must stay intact. This range suits general hygiene, engine room floors, and cargo residue that has not fully cured.

Very high pressure, from about 500-1000 bar, is chosen when tasks demand aggressive material removal: heavy marine growth on hulls, thick rust layers, hardened cargo residues, and coating or lining removal during dry-dock preparation. Operators also move into higher pressures when time on berth is limited and productivity per square meter is critical. Fussen systems are configured so flow, nozzle type, and pressure can be tuned precisely to these thresholds.

High-Flow Flushing vs High-Pressure Cutting: Which Marine Jobs Require Which?

In marine maintenance, operators must distinguish between high-flow flushing for quickly moving large volumes of water and high-pressure cutting for attacking localized, stubborn contaminants. Large cargo holds, ballast tanks, and void spaces typically benefit from high-flow systems that sweep away sludge, loose scale, and residues. By contrast, thick rust layers, hardened marine growth, and spot paint removal demand focused high-pressure jetting that concentrates energy on small, critical areas.

Large-volume flushing for tanks and cargo holds

Large-volume flushing in marine tanks and cargo holds hinges on choosing between high-flow flushing and high-pressure cutting, each serving distinct cleaning objectives. For most bulk residues, operators prioritize high-flow systems that move huge water volumes through fixed or rotating nozzles, sweeping away mud, grain dust, scale, or diluted chemicals. Pressure remains moderate, while flow rates and circulation patterns are optimized to prevent dead zones in ballast, fuel, or cargo tanks.

1.Cargo holds: High-flow flushing removes leftover cargo, fines, and wash water, preparing for the next load.

2.Ballast tanks: Continuous circulation supports sediment removal and helps meet inspection standards.

3.Offshore and bunker tanks: High-flow Fussen skids combine long-duty pumps and corrosion-resistant components to manage extended flushing campaigns safely.

High-pressure jetting for localized, stubborn contaminants

Although high-flow flushing excels at moving bulk residues, truly stubborn marine contaminants demand a shift to focused high-pressure jetting. In marine environments, this distinction defines whether operators remove soft cargo residues or attack tenacious rust scales, calcified marine growth, bitumen, and aged coatings. High-pressure jetting concentrates energy through small-orifice nozzles, delivering cutting action at 500-1000 bar with moderate flow.

Shipyards typically reserve high-flow systems for rinsing ballast tanks, cargo holds, and large decks, while Fussen’s high-pressure units are deployed for weld seam preparation, spot de-coating around repairs, flange and gasket seat cleaning, and removing localized pitting corrosion. Triplex plunger pumps, precise pressure control, and specialized rotating or pencil-jet nozzles allow targeted cleaning without over-wetting adjacent structures or wasting water.

Electric Marine Pressure Washers for Shipyards and Dockside Facilities

Electric marine pressure washers are becoming a preferred choice in shipyards and dockside facilities where consistent power supply, noise control, and operator comfort are critical. Equipped with soft-start industrial motors, these units reduce inrush current, mechanical stress, and startup shock to hoses and fittings. In many marine settings, especially enclosed or densely populated work areas, electric systems outperform diesel by offering quieter operation, zero on-site exhaust emissions, and more stable performance for long-duty cleaning shifts.

Benefits of soft-start industrial motors and quiet operation

When specified with soft-start industrial motors, electric marine pressure washers provide smoother ramp-up, reduced mechanical stress, and lower inrush currents—benefits that matter greatly in shipyards and dockside facilities with sensitive power distribution. By easing the load on switchboards and generators, these systems minimize nuisance trips and extend the life of pumps, couplings, and drive components.

Quiet operation adds another layer of value. Lower sound levels support communication between deck crews, reduce fatigue during long shifts, and help operators work safely in enclosed docks or engine-room approaches.

1.Reduced start-up shocks protect Fussen triplex plunger pumps and seals.

2.Stable, low-noise operation improves working conditions near hulls and dry docks.

3.Controlled motor acceleration supports reliable use on shared yard power networks.

When electric systems outperform diesel in marine settings

In many shipyards and dockside facilities, electric high-pressure washers deliver clear advantages over diesel-driven units, especially where consistent power and tighter environmental controls are available. Fixed berths, refit yards, and covered repair halls typically have reliable electrical infrastructure, making cable-powered systems practical and efficient.

Electric units avoid exhaust emissions, reducing ventilation demands in semi-enclosed docks, engine rooms near open access, and workshop areas. Noise levels are lower, supporting communication during hull preparation, cargo hold rinsing, and detailed coating work. With soft-start motors and precise control, electric systems provide stable pressure for long-duty shifts without fuel logistics or refueling downtime.

For these reasons, Fussen’s electric marine pressure washers are often preferred as the primary solution for shore-based, high-frequency cleaning tasks.

Diesel-Driven Units for Remote, Offshore, and Heavy-Duty Marine Operations

Diesel-driven high-pressure washers become essential when marine crews must work far from stable shore power, often for many hours at a time. Their continuous-duty performance supports demanding cleaning on remote docks, large dry docks, and offshore decks where electrical supply is limited or unreliable. This section examines how Fussen’s diesel units are configured to deliver consistent pressure, fuel efficiency, and durability under these conditions.

Continuous-duty diesel performance for long shifts

Power autonomy defines many critical marine cleaning operations, where access to stable shore power is limited or nonexistent. In these environments, diesel-driven high-pressure units must deliver continuous-duty performance over long shifts without pressure loss or overheating. Fussen’s marine-focused systems are engineered around triplex plunger pumps, optimized cooling, and fuel-efficient engines to sustain steady bar and flow outputs for demanding workdays.

Key aspects of continuous-duty diesel performance include:

1.Thermal management - engine and pump cooling systems designed to handle prolonged high-load operation.

2.Component durability - ceramic plungers, reinforced seals, and corrosion-resistant housings that maintain tolerances under constant cycling.

3.Fuel and maintenance planning - large tanks, easy filter access, and clear service intervals that keep units running through extended cleaning windows.

Ideal for remote docks, dry docks, and offshore decks

Building on the need for continuous-duty performance, diesel units prove particularly suited to marine operations where electrical infrastructure is limited, unstable, or absent. At remote docks, repair teams often rely on mobile diesel-driven washers to remove rust, marine growth, and aging coatings from hulls, ramps, and fenders without waiting for shore power or generators.

In dry docks, diesel systems deliver stable high pressure and flow for large-surface flushing, coating removal, and pre-paint preparation around the clock, even when power lines are temporarily disconnected. Offshore, compact diesel skids or containerized units can be positioned on decks to handle deck washing, riser and crane cleaning, or ballast-related tasks, supporting Fussen’s objective of reliable, independent cleaning capacity in demanding marine environments.

Explosion-Proof Pressure Washers for Hazardous Marine Environments

In hazardous marine zones where flammable vapors or combustible dusts may be present, standard pressure washers pose unacceptable ignition risks. Explosion-proof units address this by using ex-proof motors, control boxes, and switches engineered to contain or prevent sparks. These systems are particularly important for offshore platforms, tank cleaning, and certain shipyard areas that must comply with ATEX or Exd certification requirements.

Ex-proof motors, control boxes, and switches for safety

Few areas of marine maintenance demand stricter safety measures than hazardous zones where flammable gases, vapors, or dusts may be present, such as on tankers, chemical carriers, and offshore platforms. In these environments, explosion-proof motors, control boxes, and switches form the core of safe high-pressure washer design. They limit potential ignition sources while allowing operators to maintain required cleaning performance.

1.Ex-proof motors contain internal arcing and high temperatures, enabling safe operation of triplex plunger pumps during long-duty cleaning of decks, manifolds, and process areas.

2.Sealed control boxes use reinforced enclosures, organized cabling, and soft-start logic to prevent sparks while protecting electronics from salt spray.

3.Rugged switches and emergency stops provide dependable operator control, even with gloves, vibration, and wet surfaces.

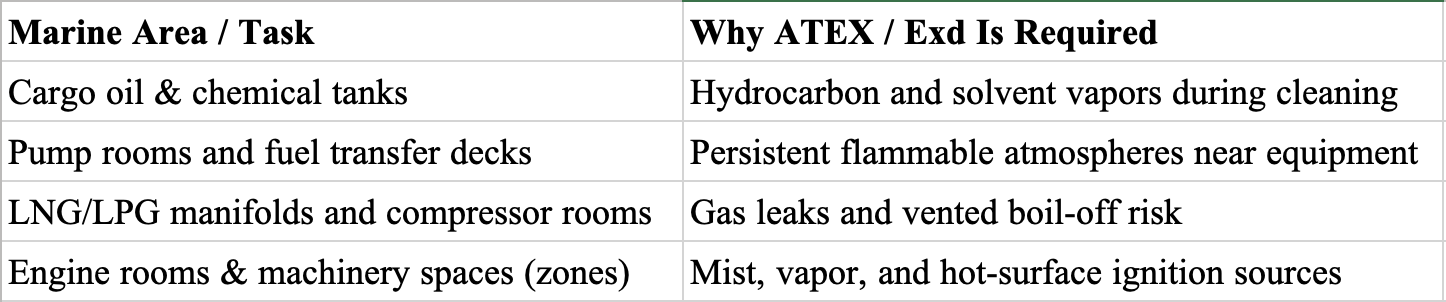

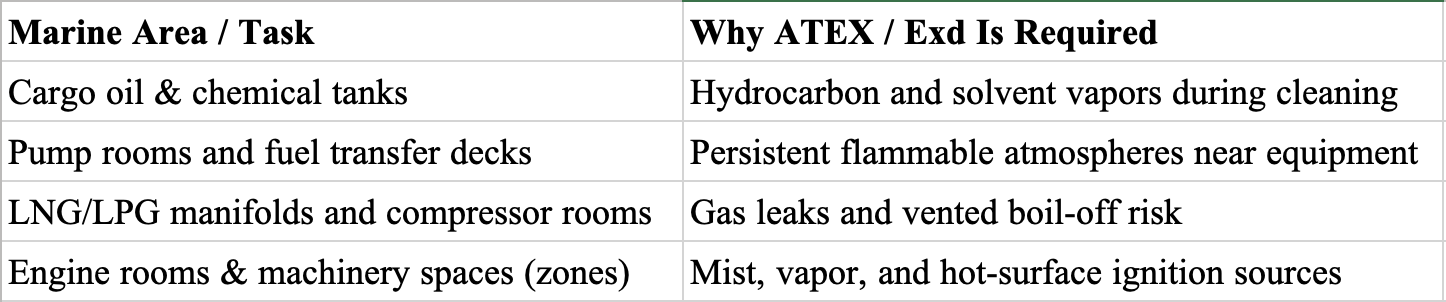

Marine applications requiring ATEX or Exd certification

Although much of a vessel can be cleaned with standard equipment, certain marine environments legally require ATEX or Exd-certified high-pressure washers to control explosion risk. Hazardous areas include fuel handling zones, chemical tankers, LNG/LPG circuits, and confined spaces where flammable vapors, mists, or dusts may accumulate. In these zones, ignition-safe design is mandatory for pumps, motors, controls, and accessories.

Fussen’s Ex-proof units address these regulated scenarios.

Key Technical Features Required for Marine-Grade High-Pressure Equipment

Marine-grade high-pressure systems depend on robust core components such as ceramic or alloy plungers, corrosion‑resistant frames, and marine‑specific sealing systems to survive continuous exposure to saltwater and abrasive contaminants. Equally critical is effective water management through low‑water protection, which prevents pump damage during fluctuating supply conditions common in shipyards and onboard operations. Stainless steel tanks and appropriate filtration complete this technical foundation by reducing contamination, protecting internal components, and stabilizing performance over long duty cycles.

Ceramic/alloy plungers, corrosion-resistant frames, and marine seals

Because high-pressure washers on ships, rigs, and in dry docks operate in some of the harshest industrial conditions, their core components must be engineered for constant exposure to salt, moisture, and abrasive contaminants. In marine-duty triplex pumps, ceramic or alloy-steel plungers resist scoring and cavitation, maintaining pressure stability during long shifts at 150-1000 bar. Corrosion-resistant frames—typically stainless or heavily coated steel—limit structural degradation, protect mounted components, and simplify washdown after contact with seawater or chemicals. Marine sealing systems, formulated for saltwater and fluctuating temperatures, prevent leakage that could quickly destroy pump internals or electric drives.

1.Ceramic plungers: wear resistance and dimensional stability.

2.Alloy plungers: impact tolerance and robustness.

3.Marine seals: extended service intervals and safer operation.

Importance of low-water protection, stainless tanks, and filtration

When a pressure washer is working hours at a time on a vessel or in a yard, low-water protection, stainless-steel water tanks, and effective filtration become fundamental safeguards rather than optional extras. Low-water protection prevents cavitation, seal damage, and overheating when supply lines fluctuate or deck tanks run low, a frequent risk during long dockside shifts.

Stainless-steel tanks resist saltwater corrosion and microbial growth, preserving water quality for consistent jet performance and reducing contamination of sensitive surfaces such as ballast tanks or cargo holds. Robust multi-stage filtration—typically including coarse strainers and fine cartridge or bag filters—removes rust flakes, sand, shell fragments, and paint chips that would otherwise score plungers, block nozzles, and shorten pump life in demanding marine cleaning cycles.

Final Recommendations for Selecting Marine-Capable High-Pressure Washers

In practice, final equipment selection in the marine sector hinges on two critical decisions: choosing between electric, diesel, or EX-proof systems, and matching pressure and flow to each cleaning task. Operators must weigh power availability, mobility needs, and hazardous-area classification against the required cleaning intensity and duty cycle. By aligning pump type, working pressure, and flow rate with real vessel and shipyard workflows, marine teams can secure both performance and long-term reliability.

Choosing between electric, diesel, and EX-proof systems

How should a marine operator decide between electric, diesel, and EX-proof high-pressure systems when each seems to solve a different problem? The choice depends less on brand and more on power availability, mobility, and safety classification in the work zone. Fussen’s range illustrates how these trade-offs play out across real shipyard and offshore scenarios.

1.Electric systems - Best where stable shore power or onboard generators exist; preferred for engine rooms, workshops, and indoor docks requiring low emissions, lower noise, and predictable running costs.

2.Diesel systems - Favoured for remote piers, offshore platforms, and dry docks where mobility, autonomy, and higher power output outweigh fuel and noise considerations.

3.EX-proof systems - Essential in ATEX-classified spaces such as tankers, ballast tanks, and fuel-handling areas where ignition risk must be rigorously controlled.

Selecting pressure, flow rate, and pump type for marine workflows

Effective marine cleaning begins with matching pressure, flow rate, and pump type to each task rather than chasing the highest bar rating available. Light deck washing and onboard hygiene typically operate efficiently around 150-250 bar with moderate flow (15-30 L/min). Hull preparation, marine growth removal, and rust stripping often demand 350-500 bar combined with higher flow (30-50 L/min) for coverage and flushing.

Ballast tank flushing, cargo hold rinsing, and dry-dock work usually benefit from large-flow units (60-120 L/min) at mid-to-high pressure for rapid bulk cleaning. Triplex plunger pumps remain the preferred choice for long-duty marine cycles, providing steady pressure, high volumetric efficiency, and compatibility with abrasive or saline environments when paired with marine-grade seals, ceramic plungers, and corrosion-resistant pump bodies.

Conclusion

high-pressure washers are indispensable to modern marine operations, tackling stubborn marine growth, salt, and oil while supporting corrosion control and safety. By matching washer type—diesel-driven, electric, or explosion-proof—to the vessel’s operating environment, operators can clean hulls, decks, tanks, and machinery efficiently. Prioritizing marine-grade construction, corrosion resistance, and appropriate pressure and flow guarantees reliable performance, reduced downtime, and safer, more predictable vessel maintenance across diverse maritime applications.