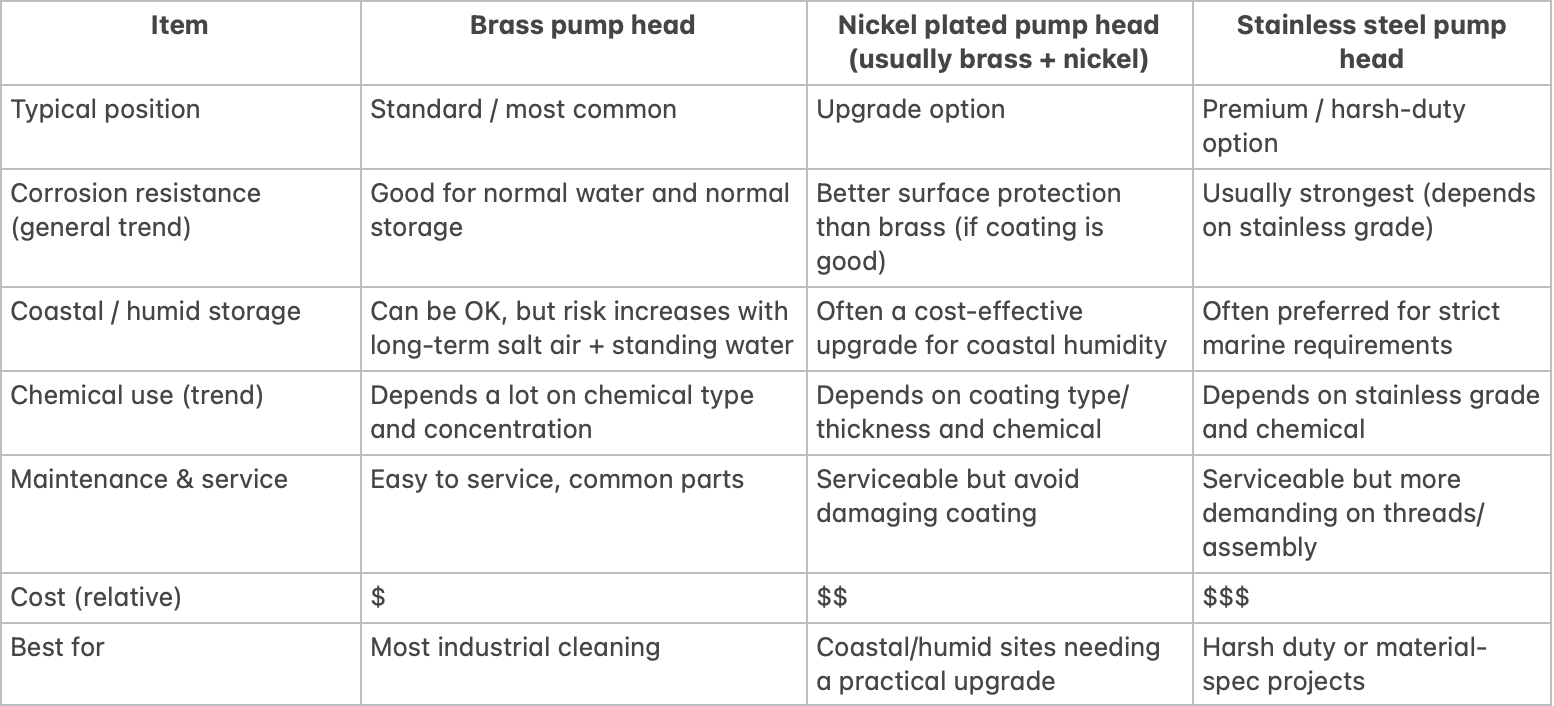

Choosing the right pump material is mainly about matching the material to your water quality, environment, and maintenance habits—not just picking the “most expensive” option. In this guide, we’ll break down three common high pressure pump material choices and show a simple way to decide.

The pump head of the brass plunger pump is made of brass. It’s widely used because it machines well, seals reliably, and offers strong value for most industrial cleaning jobs using normal water sources. In most cases, it’s the “default” option in the market.

This is where most comparisons start: brass vs stainless steel pump —because brass is the standard baseline.

A nickel plated pump is usually a brass pump head with a nickel coating on the surface (electroplated or electroless). Think of it as a “surface upgrade”:

better surface protection in humid/salty environments

easier to clean and better appearance

improved resistance to staining and surface oxidation (depending on coating quality)

Important: it’s not always a different base metal—most are brass underneath.

The pump head of the stainless steel plunger pump is made of stainless steel. Buyers typically choose stainless when the environment is harsher (coastal humidity, higher chloride exposure, certain chemical conditions) or when clients require stainless by spec.

In many projects, stainless is chosen for “environment + water chemistry” reasons more than for pressure rating.

the pump mainly uses clean/stable water

the pumps is not constantly stored in salt air

buyer wants the best value and proven reliability

This is the most common high pressure pump material choice.

the pumps works or is stored in coastal/humid environments

the customer wants “better surface protection + easier cleaning”

stainless is not required but brass feels risky

A nickel plated pump is often the best “upgrade with controlled cost.”

the project is consistently harsh (marine + humidity + chloride exposure)

the client requires stainless material by specification

water chemistry or conditions justify the higher budget

This is where stainless steel pump vs brass pump becomes a real engineering decision, not a marketing one.

If you ask these five, you’ll almost always pick the right option:

Water source: city / well / recycled water? Any high salinity or high hardness?

Hot water or cold water? Max temperature?

Any chemicals added (acid/alkali/chlorine-based)?

Stored in coastal air or humid warehouse? Will it sit with water inside?

Filtration: is there a filter, and how fine is it?

These questions are the practical foundation of how to choose pump material.

Even the best high pressure pump material can fail early if:

the pump runs dry or cavitates

filtration is missing and debris damages valves

hard water scaling builds up

the pump is stored wet for long periods in salt air

So when customers debate brass vs stainless steel pump, it’s smart to also recommend filtration and good shutdown/storage habits—those often extend service life more than upgrading material alone.