In industrial high-pressure pump systems, the high pressure pump plunger plays a decisive role in pressure stability, sealing performance, service life, and maintenance cost. Selecting the correct high pressure pump plunger material is therefore critical for reliable long-term operation.

Among the available options, ceramic, stainless steel, and aluminum alloy plungers are the most commonly discussed. But are they equally suitable for industrial applications? And how should users decide which plunger material best fits their operating conditions?

This article provides a clear engineering-based comparison of ceramic plunger, stainless steel plunger, and aluminum alloy plunger designs, with practical guidance for industrial users.

A high pressure pump plunger is a precision reciprocating component that generates pressure by moving back and forth inside the pump chamber. It works together with seals, valves, and the pump head to convert mechanical energy into high-pressure fluid flow.

Because the plunger is in constant contact with seals and working fluid, its material directly affects:

Wear resistance

Seal life

Pressure stability

Maintenance frequency

Overall pump lifespan

This makes high pressure pump plunger material selection a core design decision rather than a minor detail.

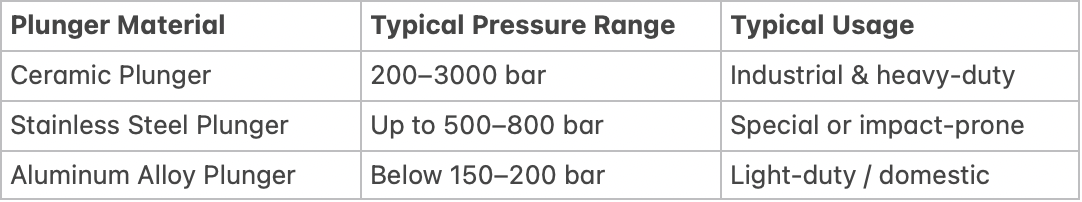

From an industrial perspective, plungers are generally classified into three categories:

While all three exist, ceramic and stainless steel plungers dominate industrial high-pressure pump applications.

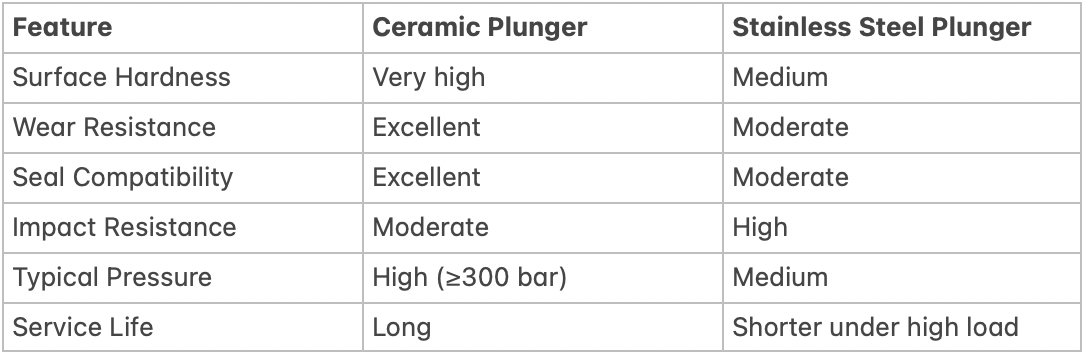

A ceramic plunger is the most widely used solution in industrial high-pressure pumps due to its superior mechanical and tribological properties.

Extremely high surface hardness

Excellent wear resistance

Very low friction coefficient

Reduced seal wear

Excellent dimensional stability under high pressure

No corrosion or rust in water-based systems

These properties allow ceramic plungers to maintain stable performance even during continuous operation at high pressure.

Marine and shipyard cleaning

Rust and paint removal

Heavy industrial surface preparation

Offshore and petrochemical maintenance

High-pressure water jetting systems

In most industrial environments, ceramic plungers deliver long service life with minimal performance degradation when operated correctly.

A stainless steel plunger is sometimes selected when operating conditions involve mechanical shock, fluctuating loads, or special fluids.

High toughness and impact resistance

Less brittle than ceramic

Better tolerance to sudden load changes

Lower surface hardness compared to ceramic

Higher friction coefficient

Faster wear during continuous high-pressure operation

Increased seal wear over time

Because of these characteristics, stainless steel plungers are generally used in medium-pressure systems or niche applications rather than continuous-duty industrial cleaning.

The comparison between ceramic vs stainless steel plunger often comes down to wear resistance versus impact tolerance.

For most industrial high-pressure cleaning applications, ceramic plungers provide superior long-term reliability, while stainless steel plungers are reserved for specific conditions.

Aluminum alloy plungers are primarily used in low-pressure and light-duty equipment.

Lightweight and low cost

Easy to manufacture

Low surface hardness

High wear rate under pressure

Limited pressure capability

Due to these limitations, aluminum plungers are not recommended for industrial high-pressure pump systems where durability and continuous operation are required.

A simplified engineering guideline is widely accepted across the industry:

Industrial high-pressure cleaning (≥300 bar): Ceramic plunger

Medium pressure or impact-prone conditions: Stainless steel plunger

Low pressure and intermittent use: Aluminum alloy plunger

Selecting the correct plunger material helps reduce downtime, extend seal life, and improve overall pump efficiency.

In industrial high-pressure pump manufacturing, material selection is not only a design choice but a reflection of long-term operational experience.

At FUSSEN, ceramic plungers are widely adopted across industrial pump ranges where continuous operation, pressure stability, and service life are critical. Through long-term field applications in marine cleaning, surface preparation, and heavy industrial environments, ceramic plungers have proven to deliver consistent performance while minimizing seal wear and maintenance requirements.

This engineering-driven approach allows high-pressure pumps to maintain reliability under demanding conditions, reinforcing the importance of selecting the right high pressure pump plunger material for industrial use.

Although ceramic, stainless steel, and aluminum alloy plungers are all available, they are not interchangeable. Each material serves a specific purpose and operating range.

For industrial applications, ceramic plungers remain the most reliable and widely adopted solution due to their superior wear resistance and long-term performance. Stainless steel plungers address niche requirements, while aluminum alloy plungers are best limited to light-duty equipment.

Understanding these differences allows engineers and buyers to make informed decisions when selecting a high pressure pump plunger for demanding industrial environments.