Heat exchanger cleaning with high-pressure washers is an essential maintenance process that targets scale, biofilm, and corrosion deposits that degrade thermal performance. By using controlled pressure, flow rate, and nozzle geometry, operators can optimize shear force on fouled surfaces while limiting tube erosion and material loss. Fussen’s 90 L/min, 1400 bar FKD diesel ultra-high-pressure washer is specifically engineered for this type of work, delivering stable pressure and consistent flow needed to remove tough deposits inside tube bundles and condensers with high precision. Its performance ensures deep cleaning while minimizing the risk of tube damage. This method suits a range of exchanger designs, but its effectiveness and safety depend heavily on correct setup, sequencing, and verification steps that are often overlooked.

Key Takeaways

·High pressure washers remove scale, biofilm, sludge, and hydrocarbons, restoring design heat transfer, pressure drop, and overall exchanger performance.

·Matching pressure, flow, and nozzle geometry to deposit type ensures effective cleaning while minimizing erosion or damage to tube and plate surfaces.

·Shell-and-tube bundles often use rotary or multi-lance hydroblasting to reach complex geometries and achieve uniform, verifiable cleanliness.

·Cleaning should be scheduled when data show rising pressure drop, degraded approach temperature, or increased energy input to maintain process setpoints.

·Documented high pressure cleaning procedures improve safety, shorten outages, and extend exchanger service life through controlled, repeatable fouling removal.

Introduction to Heat Exchanger Cleaning

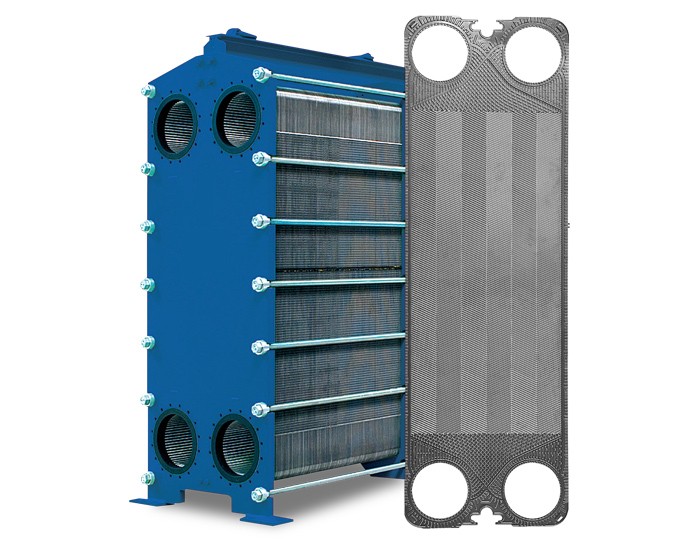

Heat exchanger cleaning is the controlled removal of fouling deposits—such as scale, corrosion products, polymers, and biofilms—from heat transfer surfaces and flow passages to restore design duty, ΔP, and reliability. In industrial service, high pressure cleaning equipment is applied to shell-and-tube and plate units because it can deliver repeatable, directional energy into constrained geometries without excessive disassembly or thermal stress. Properly specified tube bundle high pressure cleaning and plate heat exchanger high pressure cleaning rely on matching pressure, flow, and tooling to deposit type and metallurgy so that fouling is removed efficiently while maintaining surface integrity and minimizing erosion.

What is Heat Exchanger Cleaning?

In industrial process plants, heat exchanger cleaning is defined as the systematic removal of internal and external deposits from heat transfer surfaces to restore design thermal performance, pressure drop characteristics, and mechanical reliability. It encompasses planned interventions using heat exchanger cleaning equipment to eliminate fouling such as scale, polymers, corrosion products, and biological growth from shell, tube, and plate passages.

Industrial hydroblasting for heat exchangers typically applies controlled high pressure and flow to cut, shear, and dislodge deposits without exceeding allowable tube wall stresses. In shell and tube applications, tube bundle high pressure cleaning targets individual tubes, tube sheets, and channels using engineered nozzles and rigid or flexible lances. The process is defined by specified cleanliness criteria, inspection checkpoints, and verification of ΔP recovery.

Why High Pressure Washer Cleaning is Used in Industry

Across refineries, power stations, and process plants, high pressure cleaning is selected for heat exchanger maintenance because it delivers predictable fouling removal with minimal impact on base metal and surrounding equipment. Compared with chemical cleaning alone, a properly engineered heat exchanger high pressure washer provides repeatable tube heat exchanger cleaning, shorter outages, and verifiable cleanliness through ΔP and thermal performance recovery.

| Driver | Engineering Consideration | Resulting Benefit |

| Fouling variability | Adjusted pressure/flow, nozzle geometry | Controlled, targeted deposit removal |

| Asset protection | Surface integrity, erosion risk management | Extended tube and plate service life |

| Outage duration | Automated lancing, multi-lance systems | Reduced critical-path maintenance windows |

| Compliance and safety | Confined-space, wastewater, energy isolation | Documented, auditable cleaning procedures |

A high pressure fouling removal system accommodates hard scales, polymers, and biofouling while maintaining tight control over cleaning energy and substrate stress.

How Fouling Impacts Heat Exchanger Efficiency and Lifetime

Fouling in industrial heat exchangers—whether from mineral scale, biofilm, sludge, or heavy hydrocarbons—directly degrades heat transfer coefficients and increases pressure drop across tube bundles and plate packs. As deposits accumulate, operators see rising ΔP, reduced approach temperatures, higher energy consumption, and elevated risk of unplanned outages due to underperformance or tube failure. Understanding these fouling signatures and their impact on efficiency enables maintenance teams to identify when high pressure exchanger cleaning equipment and tube bundle high pressure cleaning should be scheduled to restore design performance and extend asset life.

Common Types of Fouling (Scale, Biofilm, Sludge, Hydrocarbons)

Deposits inside heat exchanger channels and tubes typically fall into four dominant categories—mineral scale, biological films, sludge, and hydrocarbon residues—each with distinct adhesion mechanisms and removal requirements. Mineral scale (e.g., CaCO3 CaSO4) forms tenacious, crystalline layers, often requiring higher-pressure industrial hydroblasting for heat exchangers and optimized nozzle geometry. Biofilms exhibit viscoelastic behavior, binding particulates and shielding under-deposit corrosion; effective heat exchanger cleaning equipment must disrupt the polymeric matrix, not only remove bulk biomass. Sludge combines corrosion products, silt, and organics, demanding tube bundle high pressure cleaning with adequate flow to mobilize settled debris. Hydrocarbon fouling often forms glassy, thermal-degradation films on hot surfaces.

| Fouling Type | Primary Challenge |

| Mineral scale | High bond strength |

| Biofilm | Elastic, re-forms rapidly |

| Sludge | Low mobility, settling |

| Hydrocarbons | Smear risk, glazing |

Performance Loss, Energy Waste, and Unplanned Downtime

Progressive thermal resistance within exchanger surfaces directly translates into reduced duty, elevated approach temperatures, and higher operating costs. As fouling layers build, overall heat transfer coefficient (U) declines, requiring higher utility temperatures, increased pump power to overcome ΔP rise, or reduced throughput. Operators lose control of thermal margins and are forced into less efficient operating points.

In shell and tube heat exchanger cleaning contexts, fouling-driven pressure drop can impair upstream equipment, destabilize column operation, and trigger protective trips. For plate heat exchanger high pressure cleaning applications, partial channel blockage produces maldistribution, hot spots, and gasket stress, shortening asset life. Deferred removal with a high pressure fouling removal system ultimately converts manageable performance drift into unplanned outages, emergency hydroblasting, and elevated lifecycle maintenance expenditure.

Signs Your Heat Exchanger Needs High Pressure Cleaning

As heat exchanger performance drifts away from design duty and operating margins tighten, maintenance teams need objective indicators that a high pressure fouling removal system should be scheduled rather than continuing to compensate with process adjustments. Primary triggers include sustained ΔT degradation at constant load, rising ΔP across the shell or tube side, and increased approach temperature in condensers or heaters.

Trending data often shows progressively higher pump power, firing rate, or chiller load to hold setpoints, alongside reduced throughput or longer batch cycle times. Frequent need to bypass units, adjust control valves to extremes, or operate closer to trip limits indicates that fouling is constricting flow paths. When these symptoms persist after minor backflushing or chemical treatment, tube bundle high pressure cleaning becomes operationally justified.

Types of Heat Exchangers Suitable for High Pressure Cleaning

In practice, high pressure cleaning strategies must be adapted to the specific geometry and materials of three primary exchanger configurations: shell-and-tube, plate and frame, and finned-tube or air-cooled units. Each design presents distinct access constraints, fouling patterns, and allowable nozzle stand-off distances that directly influence selection of industrial hydroblasting for heat exchangers, pressure/flow parameters, and specialized tooling. The following sections outline how tube bundle high pressure cleaning, plate heat exchanger high pressure cleaning, and finned surface treatment can be executed to restore thermal performance while controlling erosion risk and maintaining surface integrity.

Shell-and-Tube Heat Exchangers

Although widely deployed across refineries, petrochemical complexes, and power stations, shell-and-tube heat exchangers present some of the most demanding requirements for high pressure cleaning due to their geometry, metallurgy, and fouling patterns. Tube nests, baffles, and support plates create complex flow paths that trap hard scales, under-deposit corrosion products, and polymerized organics.

Effective shell and tube heat exchanger cleaning depends on matching industrial hydroblasting for heat exchangers to bundle design: tube ID, length, U-bends, and allowable ΔP. Tube bundle high pressure cleaning typically combines rotary lancing or multi-lance systems with controlled standoff, nozzle geometry, and stepwise pressure escalation to avoid surface damage. Operators must balance required shear stress against erosion risk, especially in copper alloys, titanium, and high-alloy stainless steels.

Plate and Frame Heat Exchangers

Plate and frame heat exchangers introduce a different set of constraints and opportunities for heat exchanger cleaning equipment compared with shell-and-tube designs, driven primarily by their narrow flow channels, gasketed joints, and highly textured plate geometries. These units are highly susceptible to particulate bridging, biofouling, and crystallized scale within chevron patterns, rapidly elevating ΔP and degrading thermal performance.

For plate heat exchanger high pressure cleaning, operators typically disassemble plate packs and employ controlled-pressure lancing or fan-jet manifolds, matching pressure and standoff distance to plate alloy, emboss depth, and gasket specifications. Industrial hydroblasting for heat exchangers must avoid cutting gaskets, distorting plates, or inducing edge erosion, requiring triplex plunger pumps with fine pressure resolution, stable flow, and tooling that maintains uniform, trackable coverage.

Finned-Tube and Air-Cooled Heat Exchangers

Where shell-and-tube and plate units concentrate fouling inside pressure boundaries, finned‑tube and air‑cooled heat exchangers present an exposed external surface that demands a different approach to heat exchanger cleaning equipment and operating parameters. Deposits include wind‑borne dust, hydrocarbons, salt, insects, pollen, and fibrous debris, often compacted at the fin roots, degrading airflow and ΔT performance.

Industrial hydroblasting for heat exchangers on air‑coolers must balance enough impact to break cohesive layers without deforming fins or driving debris deeper. Operators typically employ moderated pressures with higher flows, fan‑jet tools, and controlled standoff distance, often combined with mechanical pre‑debris removal. A high pressure fouling removal system with precise pressure regulation, uniform traverse mechanisms, and consistent nozzle geometry helps maintain fin integrity, minimize erosion risk, and restore design ΔP and duty.

High Pressure Washer vs Other Heat Exchanger Cleaning Methods

In industrial practice, heat exchanger cleaning typically relies on three primary approaches: mechanical tools (rodders, brushes, scrapers), chemical cleaning (CIP circuits, solvent or acid circulation, detergents), and hydroblasting with high pressure heat exchanger cleaning equipment. Each method imposes different hydraulic loads, access requirements, and compatibility constraints with tube metallurgy, gasket materials, and process residues. A structured comparison of these techniques, including tube bundle high pressure cleaning and plate heat exchanger high pressure cleaning, is essential to optimize fouling removal effectiveness, turnaround duration, and total maintenance cost.

Mechanical Cleaning (Rodder, Brushes, Scrapers)

Mechanical cleaning methods—such as rotary rodder systems, brushes, and scrapers—remain a core option for shell and tube heat exchanger cleaning when access, fouling characteristics, or plant constraints limit the use of high pressure exchanger cleaning equipment. These tools provide direct, mechanically constrained engagement with tube ID surfaces, allowing operators to control contact pressure, feed rate, and dwell time.

Rodder systems advance flexible shafts or rigid rods through tubes, rotating nylon, steel, or abrasive brushes sized to the tube diameter and metallurgy. Scrapers remove hard, adherent deposits but must be selected to avoid galling or scoring. Mechanical cleaning is often validated by ΔP recovery and borescope inspection. However, it can be slower and less effective in deep, tenacious scaling than properly engineered industrial hydroblasting for heat exchangers.

Chemical Cleaning (CIP, Solvents, Acids, Detergents)

While mechanical cleaning methods provide direct tube wall contact and precise bore geometry control, many plants pair or replace them with chemical cleaning strategies—CIP circuits, solvent soaks, acid descaling, and detergent surfactant washes—to address complex fouling in both shell and tube heat exchanger cleaning and plate heat exchanger high pressure cleaning regimes. Chemical programs target under-deposit corrosion, microbiological films, and tenacious inorganic scales that resist short-contact, high shear hydro-mechanical passes. Engineers value the ability to meter concentration, temperature, and contact time, integrating ΔP trending and outlet conductivity to verify completion.

·Reduce uncertainty in bundle cleanliness

·Minimize intrusive disassembly frequency

·Control risk of tube wall over-thinning

·Harmonize with metallurgical compatibility envelopes

·Stabilize thermal performance between major outages

Hydroblasting / High Pressure Washer Cleaning

In industrial settings, the selection of hydroblasting-based heat exchanger cleaning equipment versus chemical cleaning is typically governed by quantifiable impacts on downtime, operator safety, and verifiable cleaning quality. Maintenance teams must compare isolation and neutralization time, personnel exposure risk, and the ability of tube bundle high pressure cleaning to restore design heat transfer and ΔP within acceptable limits. The following section examines when industrial hydroblasting for heat exchangers, using controlled pressure/flow and appropriate tooling, becomes the preferred method over chemical descaling from an operational and lifecycle perspective.

Comparison of Downtime, Safety, and Cleaning Quality

Although “high pressure washeris a common shorthand in many plants, industrial hydroblasting and purpose-built heat exchanger cleaning equipment differ markedly from other methods when evaluated on downtime, safety, and cleaning quality. Controlled tube bundle high pressure cleaning minimizes outage duration, standardizes risk, and stabilizes ΔP recovery.

·Reduced mechanical disassembly exposure

·Shorter critical-path duration

·Predictable nozzle reaction forces

·Consistent tube ID cleanliness

·Lower unplanned rework frequency

When to Choose High Pressure Washer Over Chemical Cleaning

Because chemical circulation and soaking are firmly established in many plants, the decision to deploy high pressure washer–type heat exchanger cleaning equipment instead must be based on process, fouling morphology, and outage constraints rather than habit. Operators typically favor tube bundle high pressure cleaning when deposits are tenacious, multi-layered, poorly soluble, or under severe ΔP constraints, or when chemical compatibility, effluent volume, or schedule windows are restrictive.

Key Benefits of High Pressure Washer Cleaning for Heat Exchangers

When correctly specified and operated, industrial heat exchanger cleaning equipment using high pressure water restores design heat transfer coefficients, stabilizes ΔP, and improves overall energy efficiency across both shell-and-tube and plate units. By combining optimized pressure/flow parameters with automated tube bundle high pressure cleaning and controlled nozzle tooling, plants can shorten outage windows, reduce reliance on aggressive chemicals, and lower wastewater treatment loads. At the same time, consistent industrial hydroblasting for heat exchangers mitigates under-deposit corrosion, reduces unplanned failures, and extends exchanger service life between major overhauls.

Improved Heat Transfer and Energy Efficiency

In industrial service, improved heat transfer and energy efficiency are the primary measurable outcomes of properly executed heat exchanger cleaning using high pressure fouling removal systems. By restoring design tube ID and plate channel geometry, industrial hydroblasting for heat exchangers reduces thermal resistance introduced by scale, biofilm, polymerized organics, and corrosion byproducts. Shell and tube heat exchanger cleaning and plate heat exchanger high pressure cleaning directly translate to lower approach temperatures, reduced firing rates, and stabilized ΔT profiles across units.

Operational teams typically pursue:

·Lower fuel and steam consumption per unit throughput

·Recovery of lost overall heat transfer coefficient (U-value)

·Stabilized ΔP, enabling tighter process control

·Deferred capital expenditure on additional exchanger surface

·Predictable, data-driven energy performance across campaigns

Reduced Process Downtime and Faster Turnarounds

Although heat exchanger cleaning is often perceived as a necessary outage constraint, correctly specified heat exchanger cleaning equipment and industrial hydroblasting for heat exchangers can greatly compress critical-path duration and overall turnaround windows. Automated tube bundle high pressure cleaning frames, multi-lance systems, and rotary nozzles minimize manual intervention, reduce bundle handling, and shorten individual pass times. High-output triplex plunger pumps maintain stable pressure and flow, eliminating rework caused by inconsistent fouling removal.

When shell and tube heat exchanger cleaning and plate heat exchanger high pressure cleaning are engineered around fouling type, geometry, and ΔP limits, cleaning sequences become predictable and repeatable. This allows maintenance teams to lock in standard cycle times, improve schedule accuracy, and reliably return exchangers to service within tight production windows.

Lower Chemical Consumption and Wastewater Load

Beyond schedule compression and faster turnarounds, properly engineered heat exchanger cleaning equipment considerably reduces reliance on aggressive chemical descalants and lowers total wastewater load. By using industrial hydroblasting for heat exchangers as the primary high pressure fouling removal system, plants shift from bulk chemical dissolution to targeted mechanical removal. Triplex plunger pumps matched to tube bundle high pressure cleaning and plate heat exchanger high pressure cleaning deliver sufficient shear to dislodge tenacious deposits with minimal additive dosing.

·Less uncertainty in wastewater chemistry and permit compliance

·Reduced sludge generation and off-site disposal liability

·Lower risk of under or over‑inhibited chemical cleaning campaigns

·Improved control of metallurgy exposure to corrosive species

·More predictable OPEX for recurring shell and tube heat exchanger cleaning programs

Extended Equipment Lifetime and Fewer Emergency Repairs

Well-specified heat exchanger cleaning equipment directly influences asset life by limiting corrosion mechanisms, tube wall thinning, and gasket degradation that typically arise from repetitive chemical cleaning and uncontrolled mechanical methods. When industrial hydroblasting for heat exchangers is engineered with stable pressure, matched flow, and controlled standoff distance, the cleaning force is focused on fouling removal rather than on base metal attack.

In shell and tube heat exchanger cleaning, automated tube bundle high pressure cleaning minimizes localized over-pressurization and mechanical impact on tube-to-tubesheet joints, reducing leak initiation points and subsequent emergency repairs. For plate heat exchanger high pressure cleaning, uniform nozzle traverse protects plate embossing and gasket grooves, reducing fatigue and unplanned gasket failures. Consistent, repeatable cleaning intervals also stabilize ΔP trends and extend run length.

High Pressure Washer Technology for Heat Exchanger Cleaning

Effective heat exchanger cleaning equipment relies on correctly pairing pressure and flow ranges with the specific fouling type, whether soft biofilm, tenacious polymer deposits, or hard inorganic scale. At the core of industrial hydroblasting for heat exchangers are triplex plunger pumps and engineered nozzle geometries that control jet coherence, impact force, and stand-off behavior within tubes and plate channels. These principles extend into the selection of rotating, flexible, and multi-lance tools that enable controlled tube bundle high pressure cleaning and plate heat exchanger high pressure cleaning while protecting surface integrity and managing ΔP constraints.

Pressure and Flow Ranges for Different Fouling Types

For any industrial hydroblasting operation on heat exchangers, selecting appropriate pressure and flow ranges starts with the fouling mechanism and the exchanger geometry rather than the nominal rating of the heat exchanger cleaning equipment. Soft biofilm in plate heat exchanger high pressure cleaning is typically displaced at 150-300 bar with moderate flow to avoid gasket damage, while polymerized organics on shell and tube heat exchanger cleaning may require 800-1,500 bar and elevated impact force. Mineral scale and tenacious deposits often justify 1,500-2,500 bar within a high pressure fouling removal system, with flow sized for effective debris transport, not just cutting power.

·Avoid under-powered passes

·Prevent tube wall erosion

·Stabilize ΔP recovery

·Control wastewater loading

·Maintain predictable turnaround durations

Triplex Plunger Pumps and Nozzle Design Basics

Triplex plunger pumps sit at the core of modern heat exchanger cleaning equipment, converting shaft power into the steady high-pressure flow required for industrial hydroblasting for heat exchangers while maintaining tight control of pressure ripple and volumetric efficiency. Their three-cylinder configuration yields a more continuous pressure profile, reducing fatigue loading on lances, hoses, and tube bundle high pressure cleaning manifolds.

Plunger diameter, stroke, and crank speed are selected to deliver the target combination of pressure and flow for shell and tube heat exchanger cleaning and plate heat exchanger high pressure cleaning, while respecting NPSH, seal life, and drive power limits.

Nozzle design focuses on precise orifice sizing, jet coherence, and impact force distribution to achieve controlled, repeatable high pressure fouling removal system performance.

Rotating, Flexible, and Multi-Lance Tools for Tubes and Plates

Where straight-line jets from a fixed lance cannot adequately address complex fouling patterns or internal geometries, rotating, flexible, and multi-lance tools extend the functional capability of modern heat exchanger cleaning equipment. Rotating lances use controlled nozzle offset and rotational speed to generate circumferential impact, improving shell and tube heat exchanger cleaning in heavily scaled or under-deposit corrosion zones. Flexible lances navigate bends and U-tubes while maintaining centering and standoff, critical for industrial hydroblasting for heat exchangers in power and petrochemical service.

·Confidence in consistent wall coverage

·Relief from repeated re-pulls and re-passes

·Assurance that tube bundle high pressure cleaning is verifiable

·Reduced anxiety over tube wall loss and erosion

·Clear control of risk in plate heat exchanger high pressure cleaning

High Pressure Washer Cleaning Techniques in Practice

In practical application, high pressure washer cleaning techniques must be matched to exchanger geometry, fouling type, and access constraints, whether the task involves tube bundle cleaning with flexible lances or plate pack and plate heat exchanger cleaning. Engineers typically evaluate manual, semi-automated, and fully automated systems based on achievable nozzle stand-off distance, controlled traverse speed, rotation, and consistent delivery of the required pressure and flow to each surface. The following sections outline how these configurations are implemented in the field to optimize fouling removal efficiency, protect surface integrity, and reduce operator exposure.

Tube Bundle Cleaning with Flexible Lances

Flexible lance tube bundle cleaning represents the most versatile application of industrial hydroblasting for heat exchangers, particularly where access is constrained or full bundle extraction is impractical. Flexible lances are guided through individual tubes to deliver controlled, high velocity water jets that remove hard, adherent deposits while preserving tube integrity. Pressure, flow, nozzle geometry, and lance feed rate are matched to metallurgy, tube ID, and fouling type to guarantee reliable, repeatable outcomes.

·Relief when ΔP returns to design values after stubborn fouling removal

·Confidence in knowing tube ID is restored without unnecessary erosion

·Assurance that under-deposit corrosion sites are fully exposed and inspectable

·Satisfaction in reducing offline duration through predictable cleaning cycles

·Control gained by documenting pressures, passes, and residue load for each bundle

Plate Pack and Plate Heat Exchanger Cleaning

Several distinct considerations arise when applying high pressure fouling removal systems to plate packs and plate heat exchangers compared with shell-and-tube equipment. Gasketed plate heat exchanger high pressure cleaning demands strict control of jet angle, stand‑off distance, and reaction forces to avoid gasket displacement and plate distortion. Operators typically work with moderate pressures and elevated flows, using fan or oscillating jets to sweep corrugated channels and dislodge biofilm, scaling, and proteinaceous or polymerized deposits.

For assembled plate packs, heat exchanger cleaning equipment must direct flow across narrow gaps without inducing erosion of stainless or titanium surfaces. ΔP trends before and after industrial hydroblasting for heat exchangers guide cleaning endpoints, while inspection verifies surface integrity, uniform coverage, and absence of re-deposition in downstream channels.

Manual, Semi-Automated, and Fully Automated Systems

Equipment selection for heat exchanger cleaning extends beyond pressure and flow to the degree of mechanization: manual lancing, semi-automated positioning systems, and fully automated tube bundle high pressure cleaning robots each impose distinct constraints on procedure, risk profile, and achievable throughput. Manual tube lancing offers maximum visual control but exposes operators to higher ergonomic load, jet reaction forces, and nozzle alignment variability. Semi-automated systems stabilize lance travel, regulate speed, and maintain concentricity, improving repeatability in shell and tube heat exchanger cleaning while reducing dependence on operator skill. Fully automated industrial hydroblasting for heat exchangers standardizes feed rate, rotation, and dwell time, enabling consistent high pressure fouling removal system performance and detailed documentation.

·Reduced operator exposure

·Predictable ΔP recovery outcomes

·Lower variability in cleaning quality

·Enhanced schedule adherence

·Stronger defensibility of maintenance decisions

Safety and Risk Management in High Pressure Heat Exchanger Cleaning

Safety and risk management in industrial hydroblasting for heat exchangers must address three tightly linked domains: operator control, environmental control, and asset integrity. Effective programs formalize operator training, PPE selection, and work permits; engineer containment, drainage, and wastewater handling around the heat exchanger cleaning equipment; and define technical limits to avoid tube damage and surface erosion during tube bundle high pressure cleaning or plate heat exchanger high pressure cleaning. The following section outlines the procedures, engineering constraints, and monitoring practices required to manage these risks systematically.

Operator Training, PPE, and Work Permits

Effective high pressure heat exchanger cleaning depends as much on disciplined safety management as on pump and tooling selection, making operator training, PPE specification, and permit control integral elements of any industrial hydroblasting program. Competent crews understand nozzle reaction forces, tube bundle high pressure cleaning trajectories, and line-of-fire risks, and are certified on lockout/tagout, ΔP hazards, and emergency isolation of triplex pumps.

Mandatory PPE and work permits are treated as engineered controls, not paperwork:

·Fear of unseen jet penetration driving strict adherence to cut-resistant suits and face protection

·Anxiety about line bursts reinforcing disciplined hose inspection

·Discomfort with process upsets demanding rigorous hot-work and confined-space permits

·Concern over shell and tube heat exchanger cleaning misalignment promoting tool restraint systems

·Awareness of near-miss data shaping continuous operator requalification

Containment, Drainage, and Waste Handling

Containment and wastewater control in industrial hydroblasting for heat exchangers must be engineered with the same rigor as pump sizing or tooling selection, because the cleaning jet is only one part of the operational risk profile. Effective shell and tube heat exchanger cleaning and plate heat exchanger high pressure cleaning require defined flow paths from impact zone to final disposal, minimizing uncontrolled spread of contaminated effluent.

| Aspect | Engineering Focus | Typical Controls |

| Primary Containment | Capture of jet rebound and aerosols | Skirts, shrouds, enclosed work areas |

| Drainage Management | Directed gravity and pumped flows | Grated sumps, curbing, hose routing |

| Segregation of Streams | Separation by contaminant class | Dedicated lines, labeling, sampling |

| Waste Handling & Record | Volume, loading, disposal traceability | Meters, manifests, analytical reports |

Well-planned drainage supports compliant industrial hydroblasting for heat exchangers and efficient operation of any high pressure fouling removal system.

Preventing Tube Damage and Surface Erosion

While containment and effluent control define where the water goes, risk management for heat exchanger cleaning equipment must also address what the water jet does to the metallurgy and geometry of the exchanger itself. Controlled tube bundle high pressure cleaning and plate heat exchanger high pressure cleaning require defined operating envelopes for pressure, flow, standoff distance, and dwell time to prevent wall thinning, peening, and port edge damage. Operators rely on engineered nozzles, centralizers, and rotation control to maintain concentricity and consistent impingement angles, particularly during industrial hydroblasting for heat exchangers.

·Fear of unseen tube wall loss

·Concern over unplanned bundle retirement

·Anxiety about off-spec ΔP and throughput

·Pressure to prove cleaning integrity to auditors

·Demand for predictable, repeatable cleaning outcomes

Establishing appropriate heat exchanger cleaning frequency with industrial hydroblasting for heat exchangers requires correlating fouling rates to process conditions, materials of construction, and historical performance data. A robust maintenance plan defines predictive or preventive intervals for shell and tube heat exchanger cleaning and plate heat exchanger high pressure cleaning, then validates or adjusts those intervals using trend data rather than calendar time alone. Monitoring ΔP across the exchanger, approach temperature, and flow stability provides quantifiable trigger points for mobilizing heat exchanger cleaning equipment or a high pressure fouling removal system before efficiency loss or unplanned outages occur.

How Often Should You Clean a Heat Exchanger?

Although heat exchanger fouling is inevitable in industrial service, the ideal cleaning interval cannot be defined by calendar time alone; it must be set by performance metrics, process conditions, and risk tolerance. In practice, operators tie high pressure cleaning frequency to measurable thresholds: ΔP rise across the exchanger, lost approach temperature, and pump power penalties. When tube bundle high pressure cleaning or plate heat exchanger high pressure cleaning is delayed, fouling hardens, requiring higher pressures and longer hydroblasting time.

Operators respond most decisively when they feel:

·Loss of thermal efficiency eroding production margins

·Unplanned outages triggered by runaway ΔP

·Rising energy consumption with no visible cause

·Anxiety over under-deposit corrosion and leaks

·Pressure from stakeholders demanding predictable availability

Building a Predictive or Preventive Cleaning Schedule

A reactive approach based solely on visible performance loss or sudden ΔP excursions exposes exchangers to unnecessary thermal inefficiency, corrosion risk, and difficult fouling removal. A predictive or preventive schedule instead combines fouling tendency, duty severity, and historical cleaning data to determine ideal intervals for tube bundle high pressure cleaning and plate heat exchanger high pressure cleaning.

Engineers define cleaning frequency by correlating product mix, cooling media quality, metallurgy, and allowable fouling factors with the demonstrated effectiveness of the existing high pressure fouling removal system. Planned outages then allocate time, manpower, and heat exchanger cleaning equipment capacity to restore design heat-transfer coefficients.

Standardized intervals for industrial hydroblasting for heat exchangers reduce emergency shutdowns, stabilize production planning, and enable consistent inspection of tube condition and surfaces.

Monitoring ΔP, Temperature, and Flow to Trigger Cleaning

When should heat exchanger cleaning equipment be deployed, and based on which quantified indicators rather than intuition or calendar date alone? In well‑run plants, tube bundle high pressure cleaning is triggered by trends in ΔP, approach temperature, and flow stability, not guesswork. Rising ΔP at constant throughput indicates progressive hydraulic blockage. Simultaneously, a deteriorating temperature approach or reduced duty signals insulating fouling layers.

Operators typically define trip points such as:

·ΔP increase versus clean baseline (e.g., +25-35%)

·Approach temperature drift beyond design margins

·Pump or fan power creeping above energy targets

·Flow oscillations from partial channel restriction

·On‑stream performance falling below contractual efficiency

When these limits are reached, industrial hydroblasting for heat exchangers and plate heat exchanger high pressure cleaning are scheduled before capacity or safety margins erode.

Industry-Specific Applications for High Pressure Heat Exchanger Cleaning

Industry-specific operating conditions strongly influence how high pressure heat exchanger cleaning equipment is specified and deployed in petrochemical and refinery services, power generation and boiler feedwater systems, and marine and offshore assets. Each environment presents distinct fouling mechanisms, access constraints, metallurgies, and risk profiles that determine required pressures, flows, tooling geometries, and automation levels for tube bundle high pressure cleaning and plate heat exchanger high pressure cleaning. The following sections examine how industrial hydroblasting for heat exchangers is adapted to these sectors to optimize fouling removal effectiveness, minimize ΔP-related performance losses, and protect exchanger surface integrity.

Petrochemical and Refinery Services

Petrochemical plants and refineries impose some of the most demanding requirements on heat exchanger cleaning equipment due to complex fouling chemistries, high fluid velocities, and critical production constraints. Industrial hydroblasting for heat exchangers must address asphaltenes, polymerized films, sulfide scales, and fine particulate deposition without compromising metallurgy or tube integrity. Shell and tube heat exchanger cleaning often relies on automated tube bundle high pressure cleaning systems, integrating triplex plunger pumps, controlled rotational lances, and calibrated nozzle geometries to achieve repeatable ΔP recovery.

·Minimized unplanned shutdown risk

·Confidence in bundle cleanliness validation

·Assurance that surface integrity is preserved

·Reduced exposure hours for maintenance crews

·Reliable restoration of thermal performance

High pressure fouling removal systems in these environments demand rigorous procedure control, documented operating envelopes, and disciplined wastewater handling.

Power Generation and Boiler Feedwater Systems

Beyond petrochemical and refinery operations, heat exchanger cleaning equipment plays a central role in power generation plants, where condensers, feedwater heaters, and balance-of-plant exchangers directly affect unit efficiency, heat rate, and boiler reliability. High pressure fouling removal systems address biofouling, iron oxide, silica scaling, and organic deposits that increase ΔP, degrade vacuum, and elevate condenser backpressure. Industrial hydroblasting for heat exchangers, typically 10,000-20,000 psi with controlled flow, restores thermal performance while protecting thin-walled tubes and tube-to-tubesheet joints.

| Component | Typical Issue | Cleaning Focus |

| Main Condenser | Biofouling, silt | Tube bundle high pressure cleaning |

| HP Feedwater Heaters | Magnetite, hardness scale | Shell and tube heat exchanger cleaning |

| LP Heaters / Gland Seals | Sludge, iron oxide | High pressure fouling removal system |

Triplex plunger pumps, automated lancing, and ΔP trend analysis enable predictable, outage-driven maintenance.

Marine and Offshore Heat Exchanger Cleaning

In marine and offshore environments, heat exchanger cleaning equipment must contend with persistent seawater-induced fouling, tight machinery spaces, and stringent uptime requirements on vessels and platforms. Shell-and-tube coolers, condensers, and plate exchangers experience rapid ΔP increases from biofouling, scaling, and corrosion products, demanding predictable, repeatable tube bundle high pressure cleaning procedures. Engineers typically specify compact triplex plunger pumps with precise pressure/flow control, integrated stroke counters, and remote operation for industrial hydroblasting for heat exchangers in hazardous areas.

·Confidence in controlling ΔP rise between dry-dockings

·Assurance that high pressure fouling removal systems will not erode tube metallurgy

·Relief in minimizing unplanned shutdowns offshore

·Satisfaction in restoring design heat-transfer coefficients

·Trust in documented, auditable shell and tube heat exchanger cleaning protocols

Cost, ROI, and Productivity Considerations

Cost, ROI, and productivity for heat exchanger cleaning are best evaluated by comparing direct cleaning expenses against the quantified gains in thermal efficiency, fuel consumption reduction, and reduced outage duration. From an asset-management standpoint, plants must weigh recurring contractor fees for industrial hydroblasting for heat exchangers against the capital and lifecycle costs of in-house heat exchanger cleaning equipment and tube bundle high pressure cleaning systems. Representative case analyses typically model payback based on restored overall heat-transfer coefficients, decreased ΔP, shorter turnaround windows, and extended run lengths achieved through scheduled shell and tube heat exchanger cleaning and plate heat exchanger high pressure cleaning.

Direct Cleaning Costs vs Energy and Downtime Savings

Although line items for labor, industrial hydroblasting crews, and heat exchanger cleaning equipment can appear high on a maintenance budget, their economic impact must be evaluated against recoverable thermal efficiency, reduced ΔP, and avoided unplanned outages. When shell and tube heat exchanger cleaning or plate heat exchanger high pressure cleaning restores design U-values, fuel and power consumption decline measurably.

Plant teams respond strongly to quantifiable gains when industrial hydroblasting for heat exchangers demonstrably:

Stops creeping ΔP from silently eroding throughput

Recovers MW output or process tonnage previously “accepted” as lost

Eliminates emergency shutdowns driven by under-deposit corrosion or plugging

Shrinks cleaning windows via optimized tube bundle high pressure cleaning parameters

Converts a perceived expense into a predictable, controllable cost leveraged by a high pressure fouling removal system

Comparing Contractor Services vs In-House High Pressure Washers

Determining whether to rely on specialist contractors or invest in in‑house heat exchanger cleaning equipment requires a granular evaluation of lifecycle cost, asset utilization, and risk exposure. Contractor‐based industrial hydroblasting for heat exchangers typically offers rapid mobilization, certified operators, and access to specialized tube bundle high pressure cleaning tools, but hourly rates, standby charges, and scope creep must be modeled against ΔP recovery and throughput gains. In‑house systems demand CAPEX for triplex plunger pumps, high pressure fouling removal systems, and training, yet provide tighter schedule control and repeatable shell and tube heat exchanger cleaning quality.

| Factor | Contractor vs In‑House Consideration |

| Cost structure | Day‑rate vs amortized CAPEX/OPEX |

| Availability | Call‑out vs 24/7 internal readiness |

| Technical depth | Multi‑plant experience vs plant‑specific knowledge |

| Risk control | Outsourced liability vs direct HSE governance |

Case Examples of Payback from Regular High Pressure Cleaning

Real-world operating data from refineries, power plants, and process facilities demonstrates that systematic high pressure cleaning of heat exchangers produces measurable returns in throughput, energy intensity, and maintenance productivity. When industrial hydroblasting for heat exchangers is planned on condition-based intervals, operators observe reduced ΔP creep, stabilized approach temperatures, and shorter outage windows. Tube bundle high pressure cleaning and plate heat exchanger high pressure cleaning, when executed with correctly sized triplex plunger pumps and optimized tooling, consistently restore design heat transfer coefficients with fewer passes.

·Avoidable unplanned outages

·Escalating fuel and steam consumption

·Chronic exchanger bottlenecks limiting unit capacity

·Labor-intensive mechanical rodding and chemical soaks

·Uncertainty in inspection findings and integrity assessments

Selecting the Right High Pressure Washer System for Heat Exchanger Cleaning

Selecting heat exchanger cleaning equipment begins with correctly pairing pressure, flow, and rotary tooling to the geometry and metallurgy of the specific shell-and-tube or plate unit. From there, engineers must determine whether electric, diesel, or skid-mounted triplex pump systems best align with plant utilities, footprint constraints, and required duty cycles. Finally, they should evaluate the degree of automation and compatibility with existing tube bundle high pressure cleaning rigs, hose management systems, and control interfaces to guarantee safe, repeatable integration into current maintenance workflows.

Matching Pressure, Flow, and Tools to Heat Exchanger Type

Effective heat exchanger cleaning equipment configuration begins with aligning pressure, flow, and tooling to the specific exchanger geometry, metallurgy, fouling profile, and operating constraints. For shell and tube heat exchanger cleaning, higher pressures with moderate flow and rigid or flex-lance tools are matched to tube ID, bend radius, and allowable wall stress. Plate heat exchanger high pressure cleaning requires controlled fan-jet or rotating nozzles to protect gasket integrity while removing biofilm, scaling, or polymerized deposits.

·Minimize unplanned outages through predictable fouling removal

·Preserve tube wall thickness while achieving full ΔP recovery

·Eliminate guesswork in tool selection for complex bundles

·Reduce confined-space exposure via remotely operated systems

·Maintain confidence in compliance with site safety envelopes

Choosing Between Electric, Diesel, and Skid-Mounted Systems

Once pressure, flow, and tooling have been aligned to the exchanger geometry and fouling profile, attention shifts to how the high pressure energy is generated and packaged on site. Electric-driven heat exchanger cleaning equipment offers precise speed control, low acoustic emissions, and zero point-source exhaust, favoring indoor utilities, food plants, and marine applications with limited ventilation. Diesel-driven units provide higher power density and autonomy, suited to remote process units and offshore industrial hydroblasting for heat exchangers where electrical capacity is constrained.

Skid-mounted systems allow integration of triplex pump, filtration, and high pressure fouling removal system components into fixed or semi-permanent cleaning bays, simplifying shell and tube heat exchanger cleaning logistics, standardizing hose management, and supporting repeatable tube bundle high pressure cleaning procedures across multiple exchangers.

Automation Options and Compatibility with Existing Infrastructure

Although pump type and power source define the available hydraulic envelope, the operational performance of heat exchanger cleaning equipment increasingly depends on the level of automation and its compatibility with existing plant infrastructure. Automated tube bundle high pressure cleaning systems must integrate with existing ΔP monitoring, lockout/tagout procedures, and plant DCS or PLC networks, while preserving control over nozzle rotation speed, feed rate, and triplex pump output.

Modern industrial hydroblasting for heat exchangers relies on closed-loop automation that reduces operator exposure, stabilizes process parameters, and documents fouling removal.

·Reduced manual line-of-fire exposure

·Repeatable shell and tube heat exchanger cleaning cycles

·Tighter control of pressure, flow, and nozzle standoff

·Digital logging of passes, alarms, and hydraulic load

·Seamless interface with work permits, interlocks, and e-stop circuits

Best Practices and Operational Tips for Reliable Results

Reliable heat exchanger cleaning with high pressure fouling removal systems depends on disciplined execution before, during, and after hydroblasting. Effective practice begins with structured pre-inspection, access planning, and setup, followed by precise control of nozzle travel speed and overlap in tube bundle high pressure cleaning and plate heat exchanger high pressure cleaning. It is then closed out with systematic post-cleaning inspection, performance testing, and documentation to verify cleanliness, confirm ΔP recovery, and support repeatable maintenance programs.

Pre-Inspection, Access Planning, and Setup

Effective heat exchanger cleaning equipment deployment begins well before the pumps are started, with a structured pre‑inspection, access planning, and setup phase that directly governs cleaning quality, duration, and risk profile. Teams verify exchanger history, fouling tendencies, metallurgy, and allowable pressures to define safe operating envelopes for industrial hydroblasting for heat exchangers. Shell and tube heat exchanger cleaning demands precise bundle drawings, nozzle reach studies, and tube sheet condition checks before tube bundle high pressure cleaning starts.

·Confidence rises when every nozzle, lance, and rotary tool is pre‑validated.

·Risk falls as confined-space access and egress are rehearsed.

·Control increases with defined ΔP limits and isolation points.

·Assurance grows when wastewater routing is engineered, not improvised.

·Trust solidifies as the high pressure fouling removal system is fully function‑tested.

Optimizing Nozzle Travel Speed and Overlap

When tube bundle high pressure cleaning moves from planning to execution, nozzle travel speed and overlap become primary control variables governing deposit removal, tube wall loading, and cycle time. Travel speed is set from fouling hardness, target cleanliness, and operating pressure/flow of the heat exchanger cleaning equipment. Excessive speed leaves shadowing and residual scale; overly slow speed elevates erosion risk, pump run time, and wastewater volume.

For industrial hydroblasting for heat exchangers, overlap between successive passes must exceed the effective jet footprint, accounting for stand-off distance, rotation speed, and nozzle geometry. Shell and tube heat exchanger cleaning generally uses slower advancement and higher overlap than plate heat exchanger high pressure cleaning, where broader fan patterns and more uniform gaps permit higher traverse rates.

Post-Cleaning Inspection, Testing, and Documentation

Post-cleaning inspection, testing, and documentation convert a completed tube bundle high pressure cleaning operation into verifiable maintenance data and asset knowledge. After industrial hydroblasting for heat exchangers, disciplined verification confirms that shell and tube heat exchanger cleaning or plate heat exchanger high pressure cleaning has achieved target cleanliness without compromising metallurgy or geometry.

Technicians typically execute borescope inspections, ΔP trend comparisons, wall-thickness checks, and leak tests before release to service. A structured protocol creates traceability across multiple turnarounds and contractors.

·Relief when ΔP returns to design values

·Confidence as each tube is proven leak-tight

·Control through quantified residual fouling limits

·Assurance that surface integrity is preserved, not eroded

·Trust in documented settings for future tube bundle high pressure cleaning

Frequently Asked Questions About High Pressure Washer Heat Exchanger Cleaning

In practice, the most common questions from maintenance teams concern the potential for tube or plate damage, the selection of safe operating pressures by material, and how high pressure cleaning integrates with existing chemical or CIP regimes. From an engineering perspective, each of these points is governed by quantifiable limits: allowable wall stress, material hardness, fouling characteristics, and tooling geometry all determine whether a given heat exchanger cleaning equipment setup is conservative or aggressive. The following sections address these questions in a structured manner, linking tube bundle high pressure cleaning and plate heat exchanger high pressure cleaning parameters with material constraints, fouling removal efficiency, and overall system integrity.

Can High Pressure Washers Damage Tubes or Plates?

How easily can high pressure water damage heat exchanger tubes or plates if the process is not engineered correctly? In practice, damage risk is significant whenever pressure, standoff distance, nozzle geometry, and dwell time are not rigorously controlled. Thin-walled tubes, soft alloys, brazed joints, and gasketed plate edges are especially vulnerable to over-pressurization and concentrated jet impingement. Even with advanced heat exchanger cleaning equipment and industrial hydroblasting for heat exchangers, surface integrity can be compromised by uncontrolled jet energy and poor fixturing.

·Fear of unseen under-deposit pitting turning into through-wall failure

·Anxiety over thinning tubes from repeated aggressive tube bundle high pressure cleaning

·Concern about distorted plate profiles disrupting gasket compression

·Worry that misaligned tooling will cut tube sheets or ligaments

·Reluctance to trust contractors without documented cleaning procedures

What Pressures Are Safe for Different Materials?

Risk of tube or plate damage naturally leads to a fundamental question for any heat exchanger cleaning equipment user: what working pressures are compatible with specific tube and plate materials and geometries. In practice, safe ranges depend on metallurgy, wall thickness, support conditions, and fouling hardness, not a single “correct” pressure.

For carbon steel shell and tube heat exchanger cleaning, 400-1,000 bar is common for soft to medium scales, increasing to 1,500-2,500 bar for tenacious deposits with controlled standoff and rotation. Austenitic stainless tubes generally tolerate similar pressures but are more sensitive to under-deposit corrosion and pitting; conservative ramp-up and ΔP monitoring are preferred.

Thin titanium, Cu-Ni, and plate heat exchanger high pressure cleaning typically uses lower pressures and higher flows to limit erosion.

How to Combine High Pressure Cleaning with Chemical or CIP Processes?

Operators frequently seek to integrate high pressure heat exchanger cleaning equipment with chemical cleaning or CIP regimes to reduce downtime, address complex fouling, and control costs. In practice, ideal sequencing is: pre-rinse, chemical or CIP circulation, verification of ΔP response, then targeted tube bundle high pressure cleaning where deposits remain.

Engineers typically:

·Specify chemistry to soften scale, then apply industrial hydroblasting for heat exchangers at reduced pressure to protect metallurgy.

·Use plate heat exchanger high pressure cleaning only after CIP confirms incomplete deposit removal.

·Control nozzle geometry and standoff distance to avoid stripping passivation layers.

·Verify surface integrity via borescope or eddy current before returning to service.

·Segregate and neutralize wastewater to manage chemical and high pressure fouling removal system effluent.

Conclusion: Making High Pressure Washer Cleaning Part of Your Heat Exchanger Strategy

In modern process plants, systematic use of high pressure heat exchanger cleaning equipment is most effective when it is embedded in broader reliability, availability, and energy efficiency programs rather than treated as a reactive maintenance task. By linking tube bundle high pressure cleaning and plate heat exchanger high pressure cleaning intervals to ΔP trends, approach temperature deviations, and energy consumption metrics, facilities can quantify performance gains and optimize cleaning frequency. To achieve repeatable results and manage risks related to surface integrity, erosion, and wastewater handling, operators typically benefit from working with a specialized industrial hydroblasting supplier that understands application-specific pressures, flows, tooling, and automation requirements.

Integrating Cleaning into Reliability and Energy Efficiency Programs

Although heat exchanger cleaning is often treated as a standalone maintenance activity, it delivers the greatest value when integrated into plant reliability and energy efficiency programs as a planned, data-driven process. When industrial hydroblasting for heat exchangers is aligned with asset criticality, ΔP thresholds, and energy KPIs, tube bundle high pressure cleaning becomes a lever for controlling risk and operating cost, not just restoring capacity.

Plant teams gain greater control when they link heat exchanger cleaning equipment usage to:

·Verified fouling factors and thermal performance loss

·Predictive analytics from trendable ΔP and approach temperature

·Standardized shell and tube heat exchanger cleaning intervals

·KPIs for steam, fuel, or chiller power consumption

·Documented nozzle, pressure, and flow configurations by exchanger duty

Working with a Specialized High Pressure Washer Supplier

When heat exchanger cleaning is treated as a recurring, engineered task rather than a reactive chore, collaboration with a specialized high pressure washer supplier becomes a critical design decision, not a commodity purchase. The supplier must understand shell and tube heat exchanger cleaning, tube bundle high pressure cleaning, and plate heat exchanger high pressure cleaning across the facility’s entire asset base.

| Key Aspect | Engineering Focus |

| Application mapping | Match heat exchanger cleaning equipment to fouling types, metallurgy, ΔP limits. |

| Performance envelope | Define pressures, flows, and nozzles for industrial hydroblasting for heat exchangers. |

| Tooling strategy | Specify tube bundle high pressure cleaning lances, rotation, and indexing systems. |

| Risk controls | Address surface integrity, erosion risk, containment, wastewater handling. |

| Lifecycle support | Plan spares, calibration, training, and procedure optimization for each high pressure fouling removal system. |

How Do We Benchmark Cleaning Effectiveness Beyond ΔP and Approach Temperature Recovery?

They benchmark cleaning effectiveness using post-cleaning fouling resistance (Rf), overall heat-transfer coefficient (U), tube-side velocity-recovery checks, boroscope verification, coupon or wall-thickness measurements, solids loading in wastewater, start-up ramp behavior, and short-term ΔP stability trending under controlled process conditions.

What Nozzle Wear Monitoring Practices Reduce Underperforming Tube Bundle High Pressure Cleaning?

They reduce underperformance by enforcing nozzle-hour tracking, periodic orifice gauging, visual cone-pattern checks, flow/pressure correlation tests, hardness-based replacement intervals, batch traceability, microscopic wear inspection, and documenting deviations against baseline cleaning rates for each tube bundle high pressure cleaning configuration.

How Should Wastewater From Industrial Hydroblasting for Heat Exchangers Be Characterized and Pre-Treated?

Wastewater from industrial hydroblasting for heat exchangers is characterized via full analytical profiling (TSS, hydrocarbons, metals, pH, COD) and pre-treated by staged screening, settling, oil-water separation, pH adjustment, flocculation/filtration, and controlled discharge or licensed offsite disposal.

How Do We Qualify New High Pressure Fouling Removal Systems Without Risking Critical Exchangers?

They qualify new high pressure fouling removal systems on sacrificial or non‑critical exchangers, using stepwise pressure escalation, controlled test coupons, ΔP tracking, surface profilometry, borescope inspection, and strict parameter envelopes before authorizing use on critical assets.

What Data Should Be Logged to Optimize Long-Term Shell and Tube Heat Exchanger Cleaning?

They log inlet/outlet pressures, ΔP trend, flow, temperature, fouling type, tube ID, nozzle/orbit tool configuration, pump pressure, passes per tube, feedwater quality, outage duration, wastewater load, post-clean U-value, leak tests, and anomalies.

Conclusion

Incorporating high pressure washer cleaning into a structured maintenance program enables operators to control fouling, stabilize thermal performance, and extend heat exchanger service life. By specifying appropriate pressures, flows, and nozzle geometries, plants can maximize deposit removal while limiting tube erosion risk. When combined with proper access planning, wastewater handling, and periodic performance monitoring, high pressure cleaning becomes a repeatable, data-driven process that reduces unplanned outages, optimizes energy consumption, and improves overall asset reliability.

good blog